The allure of 3D printing lies in its ability to transform digital designs into tangible objects, layer by precise layer. Yet, as any seasoned maker will attest, the path to a perfect print is often fraught with challenges. Among the most common and frustrating 3D print troubleshooting hurdles are sagging bridges and drooping overhangs. These print quality issues can turn an otherwise flawless model into a mess of strings and distorted features, often leading to failed prints and wasted filament. This comprehensive guide will equip you with the knowledge to diagnose and effectively address these specific print anomalies, transforming your printing woes into triumphs.

Understanding why bridges sag and overhangs droop is the first step towards rectifying them. At its core, Fused Deposition Modeling (FDM) relies on depositing molten plastic onto a build plate or a previous layer, which then solidifies. When printing in mid-air, as is the case with bridges and overhangs, gravity becomes a formidable adversary. The filament needs to cool and solidify rapidly enough to hold its shape before the next layer is applied. When this delicate balance is upset, the plastic succumbs to gravity, resulting in the tell-tale signs of a struggling print.

Diagnosing sagging bridges

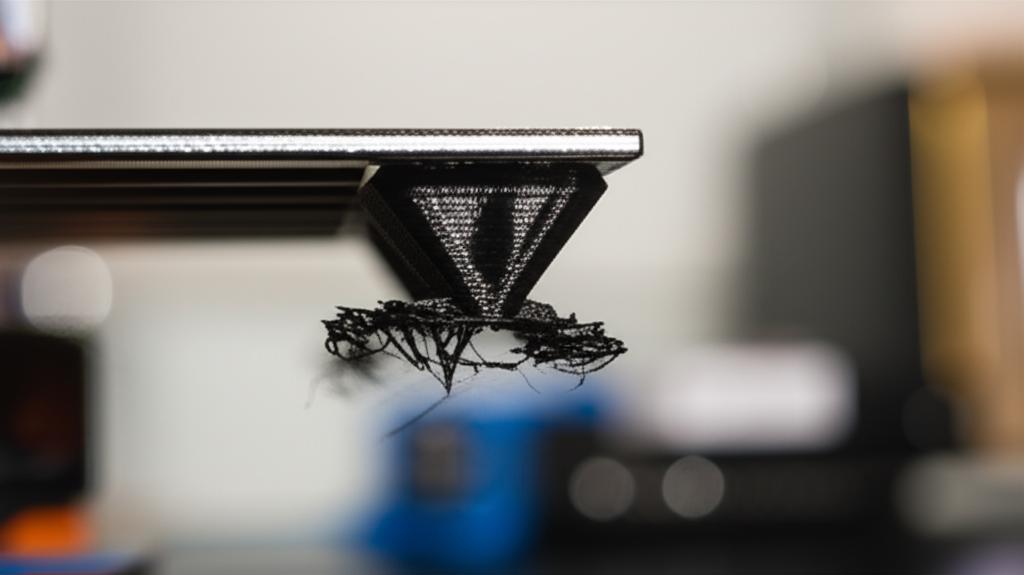

A bridge in 3D printing refers to a section of a print that spans an open gap, connecting two elevated points without any direct support from below. Imagine printing the roof of a small archway or the underside of a hollow box. The extruder lays down a line of filament across this void, relying on the material's ability to solidify before it falls. When this process goes awry, you get bridging sag – a visibly droopy or stringy underside on what should be a flat, smooth surface.

Insufficient cooling

The problem: This is arguably the most common culprit behind bridging sag. When the extruded filament doesn't cool down and solidify quickly enough as it spans the gap, it lacks the structural integrity to support its own weight. It stretches and sags under gravity before it can properly bond with the anchor points.

Symptoms: Bridges appear stringy, significantly bowed downwards, or have an uneven, rough texture on their underside. You might see individual strands of filament that haven't fully fused together, looking like tiny, stretched ropes.

Solutions:

- Increase part cooling fan speed: For bridging, you generally want your part cooling fan running at 100%. Ensure your fan is powerful enough and directed effectively at the nozzle's extrusion point.

- Improve fan duct design: A poorly designed fan duct can limit airflow or direct it inefficiently. Consider upgrading to a more effective duct that provides 360-degree cooling or focuses airflow precisely where it's needed.

- Lower print temperature slightly: While you need sufficient heat for proper extrusion, reducing the nozzle temperature by 5-10°C (within the filament's recommended range) can help the plastic solidify faster. Experiment to find the sweet spot where it still extrudes smoothly but cools quickly.

- Implement minimum layer time: Some slicers have a 'minimum layer time' setting. For small bridges, increasing this can ensure each layer has enough time to cool before the next is laid down.

Excessive print speed

The problem: If your print head moves too quickly across a bridge, the filament is stretched thinner and has even less time to cool and solidify before it loses its shape. It's like trying to walk across a tightrope too fast – you're more likely to fall.

Symptoms: Similar to insufficient cooling, but often accompanied by poor adhesion to the anchor points, resulting in bridges that look almost like a series of disconnected, droopy lines rather than a cohesive surface.

Solutions:

- Reduce bridge speed: Most modern slicers offer specific settings for 'bridge speed'. Reducing this can dramatically improve bridge quality. Start by halving your regular print speed for bridges and adjust from there.

- Reduce overall print speed: If your slicer doesn't have a specific bridge speed setting, or if other parts of your print are also struggling, a general reduction in print speed can help. This gives the filament more time to cool on all features, not just bridges.

Incorrect extrusion multiplier/flow

The problem: Extruding too much material for a given path can lead to excess plastic that simply has too much mass to support itself when bridging. This extra weight exacerbates the sagging effect.

Symptoms: Bridges appear overly thick, lumpy, and very pronounced in their sag. You might also notice general over-extrusion on other parts of your print.

Solutions:

- Calibrate E-steps: Ensure your extruder is pushing out the correct amount of filament. An uncalibrated E-step value is a common source of over-extrusion.

- Adjust flow rate (extrusion multiplier): Once E-steps are calibrated, fine-tune your flow rate in your slicer. Start by reducing it in 2.5% increments until bridges improve without causing under-extrusion elsewhere. Some advanced slicers allow for specific flow rate adjustments for bridging.

- Verify filament diameter: Ensure the filament diameter setting in your slicer matches the actual diameter of your filament. Even small discrepancies can lead to over or under-extrusion.

Lack of adequate anchor points or very long bridges

The problem: While 3D printers can perform impressive bridging, there are limits. Extremely long bridges, or bridges that terminate on very small or unstable anchor points, simply cannot defy gravity indefinitely. The initial strands have nothing firm to adhere to, or the span is too great for the plastic to hold its form.

Symptoms: Catastrophic failure of the bridge, where it completely collapses, forms a tangled mess, or detaches from one or both anchor points.

Solutions:

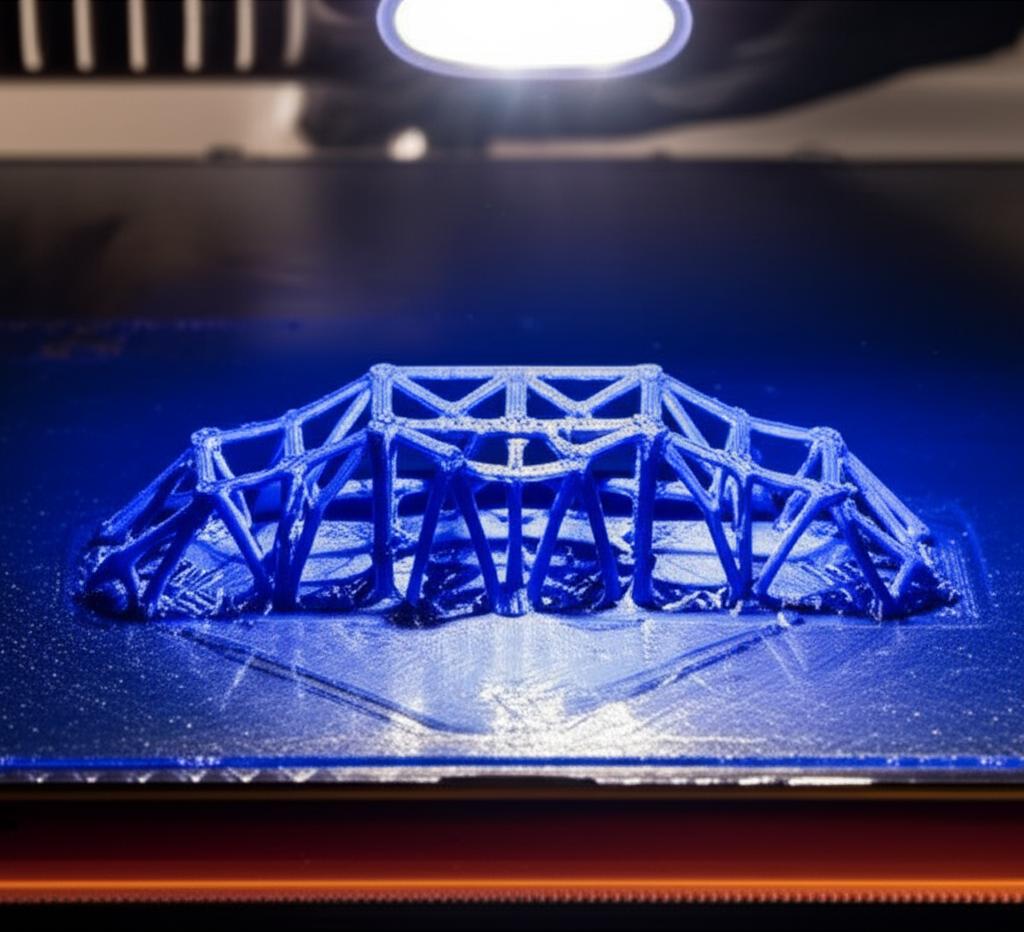

- Add sacrificial supports: For very long or complex bridges, the most reliable solution is to add temporary support structures beneath them. These supports are printed with the model and then removed afterwards.

- Reorient the part: Sometimes, simply rotating your model on the build plate can transform a challenging bridge into an easily printable overhang or even eliminate the need for a bridge entirely.

- Design for printability: If you're designing the model, consider adding chamfers, fillets, or small support features into the design itself to reduce the span of bridges.

Inadequate retraction settings

The problem: Poor retraction can lead to oozing filament during travel moves, especially when the nozzle moves across an open bridge. This excess, uncontrolled plastic adds weight and can create stringing or blobs that interfere with clean bridging.

Symptoms: Stringing across the bridge, small blobs of plastic, or an overall messy appearance, even if the primary sag is managed.

Solutions:

- Optimize retraction distance and speed: Experiment with your retraction settings. Too little retraction allows oozing; too much can cause clogs or air gaps. The ideal settings vary by printer and filament.

- Enable 'Combing' or 'Avoid printed parts when traveling': These slicer features can help the nozzle travel over already printed parts rather than open air, reducing the chance of oozing onto a bridge.

Tackling drooping overhangs

An overhang occurs when a part of your print extends outwards from the layer below it, without any direct vertical support. Think of the underside of a boat hull, the brim of a hat, or the arms of a figurine. Unlike bridges that span a gap, overhangs are built layer by layer, progressively extending further into open space. When an overhang isn't properly supported or cooled, it suffers from overhang droop, resulting in a rough, uneven, or curled-up underside that mars the aesthetic and sometimes functional integrity of the print.

Insufficient cooling for overhangs

The problem: Just like with bridges, inadequate cooling is a primary cause of overhang droop. As the nozzle extrudes plastic into thin air, the material needs to solidify almost instantly to maintain its shape. If it stays molten for too long, gravity pulls it downwards, leading to curling or drooping.

Symptoms: The underside of overhangs appears rough, bumpy, or "gooey." You might see layers curling upwards at the edges (known as "elephant's foot" if it occurs on initial layers, or general curling on upper overhangs), or a distinct downward sag on the most extreme angles.

Solutions:

- Maximize part cooling fan speed: Ensure your fan is at 100% for overhangs.

- Improve fan duct efficiency: A well-designed fan duct that directs airflow directly to the nozzle tip from multiple angles (e.g., a ring duct) is crucial for overhang performance.

- Lower print temperature: Reducing the extrusion temperature (within the material's limits) helps the plastic solidify faster, reducing the time it has to deform under gravity.

- Increase minimum layer time: This setting forces the printer to pause or slow down on very small layers, giving the plastic more time to cool before the next layer is deposited. This is particularly effective for small, detailed overhangs.

Excessive print temperature

The problem: Printing too hot keeps the filament in a molten state for longer, making it more susceptible to gravity's pull. It also increases the chances of stringing and oozing, further exacerbating overhang droop.

Symptoms: Gooey, stringy overhangs that lack definition. The plastic may appear overly shiny or wet immediately after extrusion.

Solutions:

- Find the optimal print temperature: Perform a temperature tower test for your specific filament to identify the lowest temperature at which it still extrudes reliably and produces good layer adhesion.

- Adjust for specific materials: Different filaments have different temperature requirements. PLA generally handles overhangs better at lower temperatures than ABS or PETG.

Print speed too high for overhangs

The problem: When the print head moves too quickly, especially on the outer perimeters of an overhang, there isn't enough time for the extruded plastic to cool and bond properly before the next layer is laid down. This can lead to poor layer adhesion and deformation.

Symptoms: Rough, inconsistent surfaces on the underside of overhangs. Layers may appear to be peeling or separating, indicating poor adhesion.

Solutions:

- Reduce outer wall/perimeter speed: Many slicers allow you to set different speeds for inner and outer walls. Reducing the outer wall speed specifically for overhangs can make a significant difference.

- Utilize 'slow down for overhangs' settings: Some advanced slicers have features that automatically reduce print speed when encountering overhangs, based on the angle.

Layer height and overhang angle

The problem: The steeper the overhang angle (i.e., closer to 90 degrees from the vertical), the less support each new layer receives from the layer below. Larger layer heights also mean less overlap between successive layers, further reducing support and increasing the likelihood of droop.

Symptoms: More pronounced sagging on steeper overhangs, often leading to a 'stair-stepping' effect or complete collapse if the angle is too extreme.

Solutions:

- Reduce layer height: Printing with a smaller layer height provides more surface area for subsequent layers to adhere to, improving overhang quality. This comes at the cost of increased print time.

- Optimize overhang angle: While not always possible, if you're designing the part, try to keep overhang angles below 45-60 degrees from the vertical if printing without supports.

- Consider 'variable layer height' (adaptive layers): Some slicers can automatically adjust layer height for different sections of the print, using smaller layers for overhangs and larger ones for simpler sections.

Z-offset issues for initial overhang layers

The problem: If the Z-offset is slightly too high, the very first layers of an overhang (or any layer, for that matter) might not be properly squished onto the previous layer. This leads to poor adhesion, which is magnified on unsupported overhangs.

Symptoms: The initial layers of an overhang curl upwards or detach from the main body of the print, often leading to subsequent layer delamination.

Solutions:

- Calibrate Z-offset precisely: Ensure your first layer is properly compressed onto the build plate, and subsequent layers are laid down with optimal squish.

- Ensure a clean build surface: A dirty or oily build plate can prevent proper adhesion, especially on the critical first few layers of an overhang.

Lack of supports for extreme overhangs

The problem: There's a limit to what an FDM printer can achieve without assistance. Overhangs exceeding a certain angle (typically around 60-70 degrees from vertical, depending on material and cooling) will inevitably droop or fail without external support.

Symptoms: Severe deformation, spaghetti-like extrusion, or complete collapse of the overhang section.

Solutions:

- Add support structures: This is the most reliable method for printing extreme overhangs. Slicers offer various support types (e.g., tree supports, normal supports) and customizable settings (density, angle, Z-gap).

- Optimize support settings: Experiment with support density, support angle threshold, and the Z-gap (distance between support and model) to find a balance between easy removal and effective support.

- Reorient the part: Just like with bridges, rotating your model can sometimes minimize or eliminate the need for supports on overhangs.

General 3D print troubleshooting tips for print quality issues

Addressing bridging sag and overhang droop often involves a holistic approach to your printer's setup and settings. Here are some overarching tips to improve overall print quality issues:

Calibrate your printer meticulously: Foundational calibration is paramount. Ensure your E-steps (extruder steps per millimeter) are accurate to prevent over or under-extrusion. Perform PID tuning for your hotend to maintain a stable print temperature. Most importantly, achieve a perfectly level and appropriately Z-offsetted print bed. A good first layer is the bedrock of a successful print, especially when dealing with complex geometries that include bridges and overhangs.

Choose the right material: Not all filaments are created equal when it comes to bridging and overhang performance. PLA (Polylactic Acid) generally excels in these areas due to its lower melting point and faster cooling properties. ABS (Acrylonitrile Butadiene Styrene) and PETG (Polyethylene Terephthalate Glycol-modified) are more prone to drooping and warping, requiring more precise cooling and temperature control. If you're struggling, consider switching to a more forgiving material for parts with significant overhangs.

Master your slicer settings: Your slicer is your most powerful tool for fine-tuning print quality. Dive deep into settings beyond the basics. Look for specific options like 'bridge speed,' 'overhang speed,' 'minimum layer time,' 'fan speed overrides for bridges/overhangs,' and 'support generation parameters.' Understanding how these settings interact with your material and printer is key to overcoming persistent print quality issues.

Control environmental factors: The ambient environment can significantly impact cooling and material behavior. Drafts from open windows or air conditioning can cause uneven cooling, leading to warping and poor overhang performance. Printing in an enclosure can help maintain a stable temperature, particularly for materials like ABS, which are sensitive to temperature fluctuations. However, for PLA, excessive enclosure heat can hinder cooling, so careful management is needed.

Perform regular printer maintenance: A well-maintained printer performs better. Regularly clean your nozzle to prevent partial clogs that can cause inconsistent extrusion. Check and tighten belts to ensure smooth, accurate movement of the print head. Lubricate linear rails or rods to reduce friction. A wobbly print head or loose components will exacerbate any print quality issues, especially on delicate features like bridges and overhangs.

Utilize test prints: Don't guess; test. There are numerous excellent test models available on platforms like Thingiverse or Printables specifically designed to evaluate bridging and overhang performance. Print overhang test towers to determine your printer's maximum unsupported angle and optimal cooling settings. Use bridging torture tests to fine-tune your bridge speed and flow. These small, quick prints provide invaluable diagnostic feedback without wasting large amounts of filament on failed prints.

Preventing layer delamination and failed prints

The consequences of unaddressed bridging sag and overhang droop extend beyond mere cosmetic flaws. A poorly formed bridge or a severely drooping overhang creates a weak point in your print. Subsequent layers laid upon these compromised foundations may not adhere properly, leading to layer delamination – where layers peel apart – or even a complete collapse of the print, resulting in outright failed prints. Addressing these issues proactively is critical for the structural integrity and success of your models.

By systematically diagnosing the root causes and applying the appropriate solutions outlined above, you can significantly improve your printer's ability to handle challenging geometries. Remember that 3D print troubleshooting is an iterative process of observation, adjustment, and testing. Each filament, each printer, and each model presents its own unique set of variables. Embrace the experimentation, learn from each failed print, and you'll soon master the art of producing flawless bridges and pristine overhangs, elevating your overall print quality issues to a professional standard.