In the ever-evolving landscape of additive manufacturing, traditional layer-by-layer 3D printing methods have long been the industry standard. However, a new paradigm is emerging, promising to redefine the very notion of speed and material capabilities: computed axial lithography (CAL). This innovative approach, a form of volumetric 3D printing, has captivated researchers and industry professionals alike, offering a compelling alternative to established techniques. Understanding CAL’s distinct features, particularly its cost structures and material versatility, in comparison to other advanced 3D printing solutions, is crucial for those navigating the cutting edge of manufacturing.

What is computed axial lithography (CAL)?

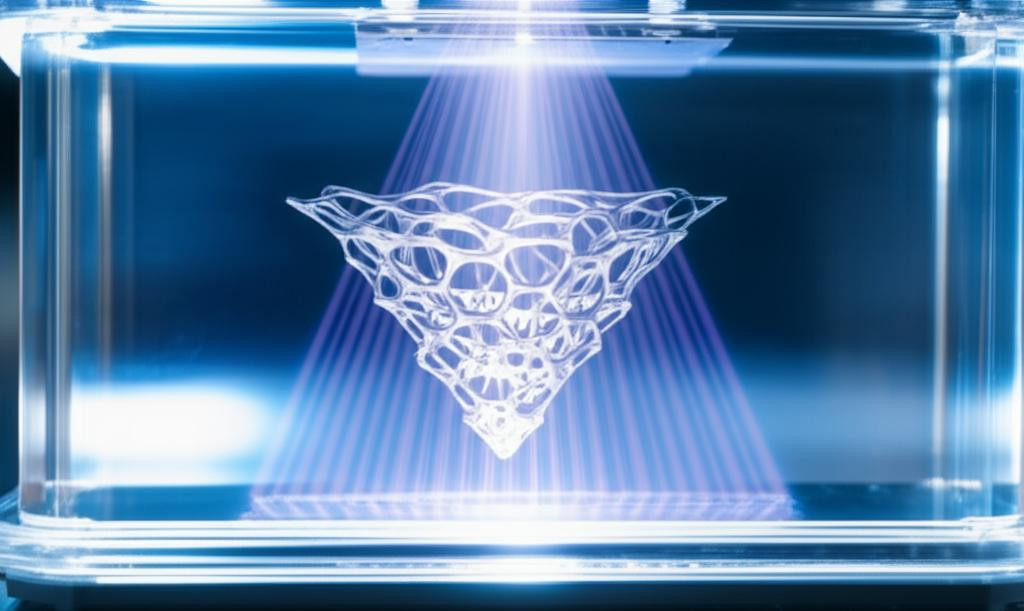

At its core, computed axial lithography represents a radical departure from conventional additive manufacturing. Instead of building objects slice by slice, CAL cures an entire volume of photosensitive resin simultaneously. This is achieved by projecting a sequence of two-dimensional light patterns from multiple angles onto a rotating vial of resin. Much like a CT scan reconstructs a 3D image from 2D X-ray projections, CAL reverses this process: it uses computed tomography principles to project light patterns that, when integrated over time and rotation, selectively solidify the desired 3D object within the resin volume.

- Volumetric curing: The key differentiator is the simultaneous curing of the entire object, rather than incremental layer formation.

- Light-based process: Utilizes specific wavelengths of light to initiate polymerization in photopolymer resins.

- Dynamic projection: A series of calculated light patterns are projected onto a rotating resin vat.

This method circumvents many of the speed limitations inherent in layer-by-layer processes, as print time becomes largely independent of object complexity or height. The result is an unprecedented level of print speed for certain applications, making CAL a frontrunner in high-speed additive manufacturing.

The promise of CAL: speed and material versatility

The allure of CAL 3D printing stems primarily from two groundbreaking advantages: its incredible print speed and its potential for unparalleled material versatility.

Unmatched print speed

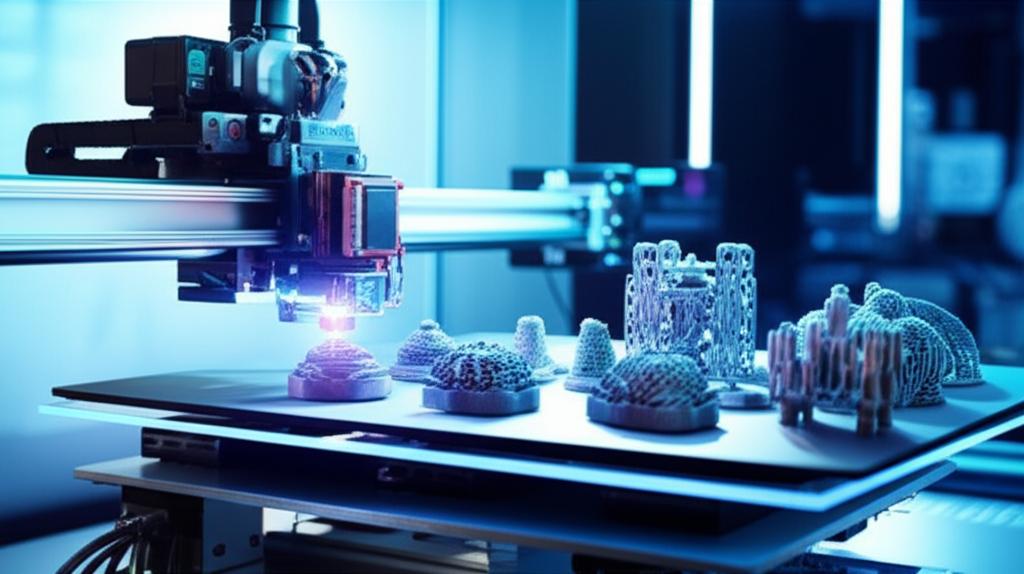

Traditional 3D printing, even advanced stereolithography (SLA) or digital light processing (DLP), is constrained by the need to cure and then often separate each layer before moving to the next. This sequential process inherently limits throughput. CAL, by contrast, eliminates these bottlenecks. Since the entire object is formed within a single curing cycle, the print speed is dramatically accelerated. Complex geometries and intricate internal structures, which would typically add significant time to layer-based prints, are produced almost as quickly as simpler forms with CAL. This makes it an ideal candidate for rapid prototyping and high-volume, small-part manufacturing where speed is paramount.

Expanding material horizons

One of the most exciting prospects of computed axial lithography is its capacity to work with a broader range of materials than many existing photopolymerization techniques. Layer-by-layer methods often struggle with highly viscous, opaque, or particle-laden resins because light penetration and layer separation become problematic. CAL, however, projects light through the entire volume, allowing for:

- Opaque resins: The volumetric curing mechanism can overcome the limited light penetration that hinders other methods, opening doors for materials with fillers or pigments.

- Highly viscous materials: Without the need for precise layer spreading or recoating, CAL can process resins that are too thick for conventional techniques.

- Biocompatible and hydrogel materials: The gentle, non-contact nature of the volumetric process, combined with the ability to print within a liquid medium, makes CAL particularly well-suited for delicate biological materials and hydrogels, which are crucial for medical and tissue engineering applications.

- Isotropic properties: Because the object is cured volumetrically rather than layer by layer, CAL prints often exhibit more uniform mechanical properties in all directions, reducing anisotropy and improving part strength and reliability.

This expanded material palette has significant implications for fields ranging from biomedical devices and soft robotics to micro-optics and custom electronics, where specialized material properties are often a prerequisite.

Comparing cost structures: CAL versus other advanced 3D printing solutions

When evaluating emerging technologies like CAL, a crucial consideration is its economic viability relative to established or alternative advanced 3D printing methods. Analyzing cost structures involves looking beyond just the initial purchase price to encompass operational expenses, material costs, and overall throughput.

Initial investment

- Computed Axial Lithography (CAL): As a nascent and highly specialized technology, the initial investment in a CAL 3D printing system can be substantial. These systems often involve advanced optical components, precise rotation mechanisms, and sophisticated computational power for generating light patterns. Early adopters and research institutions typically bear higher R&D costs embedded in the equipment price.

- Volumetric 3D printing (other forms): While CAL is a type of volumetric printing, other volumetric approaches (e.g., those using single-shot projections or different light sources) may have varying initial costs depending on their maturity and complexity.

- Advanced Stereolithography (SLA) / Digital Light Processing (DLP): High-end industrial SLA and DLP systems also represent significant capital expenditures. However, as more mature technologies, there are a wider range of options available, from desktop units to large-format industrial machines, offering more flexibility in initial investment depending on scale and precision requirements.

- Material Jetting (MJ) / Binder Jetting (BJ): These technologies, while different in principle, also demand substantial initial investments for industrial-grade systems, often due to complex printhead arrays and material handling systems.

For many, the higher upfront cost of CAL systems reflects their cutting-edge nature and the specialized engineering involved. As the technology matures and scales, these costs may trend downwards, but currently, they represent a barrier to entry for smaller operations.

Operational costs

Operational costs encompass materials, energy consumption, maintenance, and labor.

- CAL 3D printing:

- Material costs: CAL often requires specialized photopolymer resins optimized for volumetric curing. While the range of compatible materials is expanding, these bespoke resins can be more expensive than standard resins used in mature SLA/DLP systems. However, the ability to use more viscous or opaque resins might allow for novel material formulations that offer performance benefits justifying the cost.

- Energy consumption: The light source and rotation mechanism consume power, but the rapid print times might lead to lower energy consumption per part compared to slower, layer-by-layer processes that run for longer durations.

- Maintenance: Maintenance requirements involve optical system calibration and resin handling. The absence of moving parts like build platforms moving up and down for each layer might reduce mechanical wear.

- Labor: Automated post-processing could reduce labor, but initial setup and calibration might require specialized skills.

- Advanced SLA/DLP:

- Material costs: A wide variety of photopolymer resins are available, with prices varying significantly based on properties (e.g., standard, engineering-grade, biocompatible). Economies of scale often make standard resins more cost-effective.

- Energy consumption: Continuous laser or projector operation, along with platform movement, contributes to energy usage.

- Maintenance: Regular cleaning of resin vats, projector/laser maintenance, and build platform upkeep are typical.

- Labor: Post-processing (washing, UV curing, support removal) can be labor-intensive, especially for complex parts.

The cost per part in CAL can be significantly reduced by its speed, especially for high-throughput applications. If a CAL system can produce parts orders of magnitude faster, the amortized cost of the machine and even the higher material cost per unit might become competitive, particularly when considering the opportunity cost of slower production times.

Scalability and throughput

Scalability refers to the ability to increase production capacity, while throughput measures the rate of output.

- CAL 3D printing: CAL excels in throughput for specific part sizes. Its volumetric nature means print time is largely independent of part height, making it extremely fast for small to medium-sized objects. Scaling up might involve using larger resin volumes and more powerful light sources, or simply deploying multiple CAL units.

- Advanced SLA/DLP: These technologies scale by increasing build volume (larger platforms) or by using multiple printheads/projectors. While print time is dependent on part height, parallel processing (e.g., printing many small parts simultaneously across the build platform) can achieve high throughput for batch production.

For applications demanding extremely rapid production of intricate, relatively small components, CAL's throughput can offer a distinct economic advantage, offsetting potentially higher initial or material costs. The economic benefit becomes most apparent when production bottlenecks are eliminated, and time-to-market is critical.

Challenges and future outlook

While computed axial lithography presents a compelling vision for the future of 3D printing, it is not without its challenges. The technology is still relatively nascent, and significant research and development are ongoing to address current limitations.

Current limitations

- Limited build volume: Current CAL systems are typically restricted to smaller build volumes compared to some industrial SLA or FDM machines. Scaling up the volumetric curing process to large parts presents engineering hurdles related to light penetration and resin management.

- Material development: While CAL offers excellent material versatility, the development of a broad catalog of commercially available, optimized resins is still in its early stages.

- Post-processing: Although the core printing is fast, post-processing steps such as cleaning and final curing still exist, similar to other resin-based methods.

- Computational complexity: Generating the precise light projection patterns for complex geometries requires significant computational power and sophisticated algorithms.

Future outlook

Despite these challenges, the trajectory for CAL is promising. Continued advancements in:

- Optical systems: More powerful and precise light sources will enable larger build volumes and faster curing.

- Material science: Dedicated research into new photopolymers will unlock even greater material versatility, including smart materials and multi-material printing capabilities.

- Computational algorithms: Improved software will enhance the efficiency and accuracy of light pattern generation, potentially simplifying the user experience.

- Integration: As CAL matures, it is likely to be integrated into more comprehensive manufacturing workflows, potentially alongside other additive or subtractive techniques.

The potential for CAL to revolutionize rapid prototyping, on-demand manufacturing, and specialized applications in medical and aerospace fields is immense. Its unique ability to combine high-speed additive manufacturing with an expanded material palette positions it as a transformative technology.

Conclusion

Computed axial lithography (CAL) stands as a testament to the ongoing innovation in the field of 3D printing. By embracing a volumetric approach, it offers a compelling blend of unprecedented print speed and remarkable material versatility, pushing the boundaries of what's possible in additive manufacturing. When evaluating CAL against other advanced 3D printing solutions, it becomes clear that while the initial investment might be higher and specialized materials are often required, the potential for high-speed additive manufacturing and the ability to work with previously unprintable materials can translate into significant long-term benefits and a competitive edge.

Ultimately, the decision to adopt CAL 3D printing or another advanced method hinges on specific application requirements. For industries where rapid prototyping, high-volume production of small, intricate parts, or the use of novel, delicate, or opaque materials is critical, CAL presents a powerful and potentially transformative option. As the technology continues to mature, its cost structures are likely to become more competitive, solidifying its place as a cornerstone of next-generation additive manufacturing.