In the relentless pursuit of perfect prints, 3D printer enthusiasts often meticulously calibrate their machines, fine-tune slicer settings, and experiment with exotic filaments. Yet, a crucial aspect of machine maintenance, one that profoundly impacts both print quality and longevity, frequently gets overlooked: **linear rail lubrication**. These silent workhorses, guiding your printer's motion systems, are the backbone of precision. Neglecting their care can lead to a cascade of issues, from subtle print artifacts to premature component failure. This comprehensive guide delves into the world of **linear rail lubrication**, equipping you with the knowledge to keep your 3D printer running like a well-oiled machine.

Deconstructing the need: Why linear rail lubrication isn't optional

At its core, lubrication is about managing friction. In a 3D printer, linear rails, whether they use recirculating ball bearings or rollers, rely on smooth, unimpeded motion. Without adequate lubrication, the intricate dance between moving parts transforms into a grinding struggle, leading to a host of detrimental effects:

- Increased Friction and Wear: Metal-on-metal contact, even at a microscopic level, generates heat and causes abrasive wear. This not only degrades the rail surfaces and bearing balls but also introduces play into the system, directly compromising positional accuracy.

- Compromised Print Quality: Uneven friction can manifest as 'ghosting' or 'ringing' artifacts on your prints, where vibrations or inconsistent motion are subtly etched into the layers. A lack of **smooth motion** can also lead to inconsistent extrusion, layer shifts, and overall reduced **print quality**.

- Elevated Noise Levels: A dry rail system often announces its distress with squeaks, groans, and increased operational noise, indicating undue stress on components.

- Reduced Lifespan of Components: The cumulative effect of friction and wear significantly shortens the operational life of your **3D printer rails**, bearings, and even connected stepper motors, leading to costly replacements and downtime.

- Increased Power Consumption: Overcoming excessive friction requires more energy, placing additional strain on your stepper motors and power supply.

Understanding these consequences underscores that proper **rail maintenance**, particularly lubrication, isn't just a recommendation—it's an imperative for anyone serious about the performance and longevity of their 3D printer.

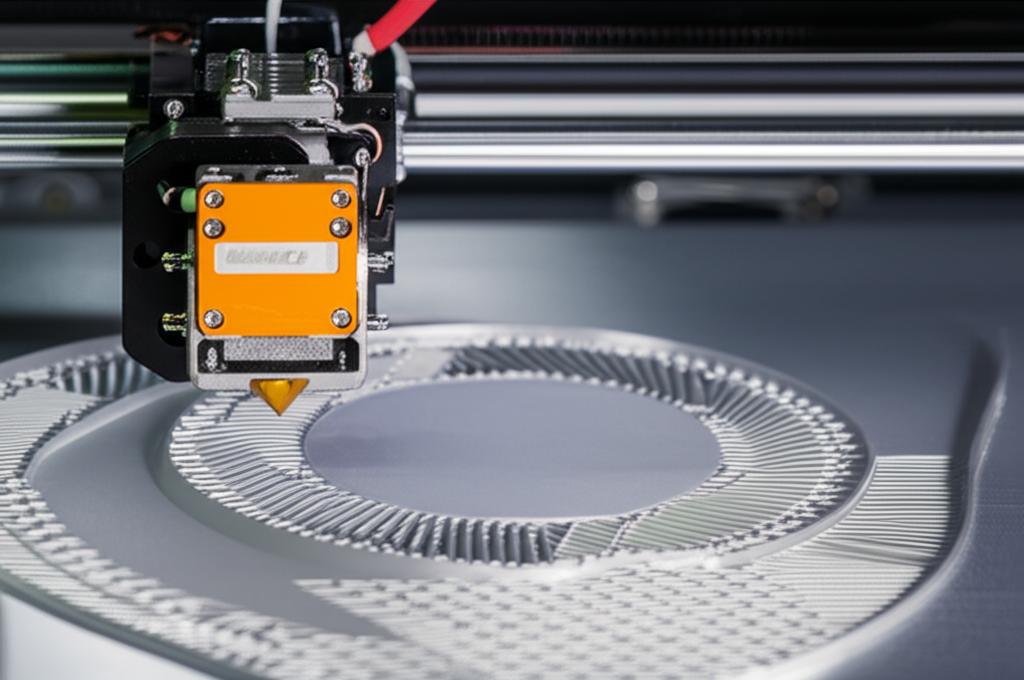

Anatomy of motion: Understanding your 3D printer's linear rails

Before diving into lubrication techniques, it's essential to understand the components you're maintaining. Most 3D printers utilize one of two primary types of linear motion systems, or a combination thereof:

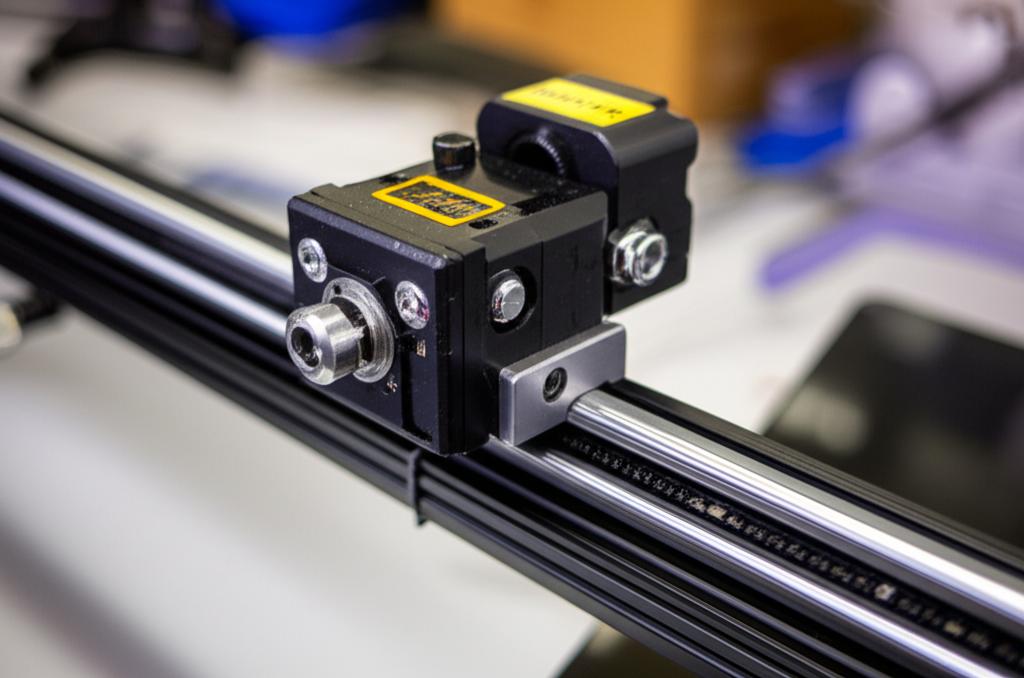

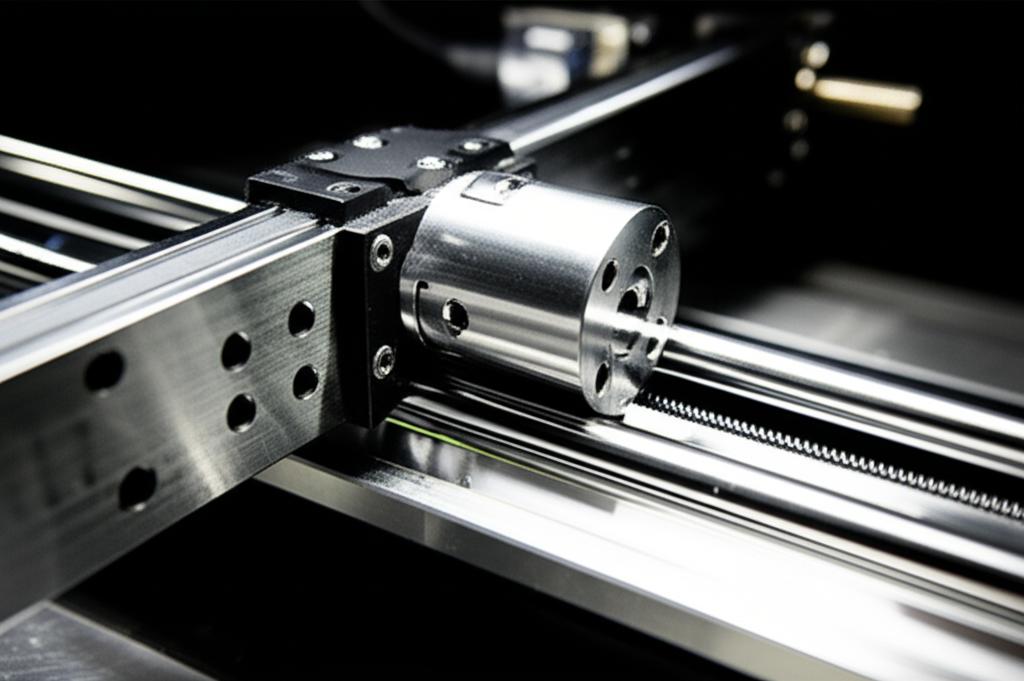

Profile linear guide rails (e.g., MGN, HGR series)

These are arguably the most common and highest-performance linear motion systems found in modern 3D printers. They consist of a hardened steel rail with precisely ground raceways and a bearing block (carriage) that contains recirculating ball bearings. These balls roll within the raceways, providing extremely low friction and high rigidity. Key lubrication points include:

- The Ball Bearings: The tiny spheres within the carriage are the primary friction points.

- The Raceways: The grooves on both the rail and the carriage where the balls run.

- End Caps and Wipers: While primarily for sealing, some lubrication can help these components remain flexible and effective.

Smooth rods and linear bearings (e.g., LM8UU, SCS8UU)

Often found in more budget-friendly printers, these systems use polished steel rods (smooth rods) and linear bearings. These bearings can be either ball-type (like LM8UU) or polymer-based (like Igus Drylin). For ball-type linear bearings, lubrication is critical for the internal balls. For polymer bearings, lubrication is generally not required and can even be detrimental, as they are designed to be self-lubricating. This guide focuses primarily on ball-type linear rails and bearings.

The lubricant spectrum: Oils vs. greases and their nuances

Choosing the right lubricant is paramount. The two main categories, oils and greases, each have distinct properties, advantages, and disadvantages, making them suitable for different applications and maintenance philosophies.

Lubricating oils

Oils are liquid lubricants characterized by their viscosity and ability to penetrate small spaces. They form a thin film between moving surfaces.

- Characteristics: Oils are rated by their kinematic viscosity (e.g., ISO VG 32, VG 46), which indicates their flow resistance. They often contain additives to improve film strength, corrosion resistance, and anti-wear properties.

- Pros:

- Excellent for high-speed, light-load applications: Their low viscosity allows for rapid movement with minimal resistance.

- Cleaner application: Generally less messy than grease, and less likely to attract large debris.

- Good for initial break-in: Can help flush out manufacturing debris.

- Heat dissipation: Oils can help carry away heat generated by friction.

- Cons:

- Shorter film life: Oils tend to migrate and evaporate more quickly, requiring more frequent reapplication.

- Less effective under heavy shock loads: The thin film can be broken down under extreme pressure.

- Can migrate/drip: Especially in open systems, oil can drip onto other components or the print bed.

- Specific Types for 3D Printers: Light machine oil (e.g., sewing machine oil, clipper oil) can be used, but specialized linear rail oils (often with ISO VG ratings around 32-46) are formulated for better performance and longevity in precision applications. These often contain anti-corrosion and anti-wear additives.

Lubricating greases

Greases are semi-solid lubricants, typically consisting of a base oil suspended in a thickener (e.g., lithium, calcium, synthetic polymers). This structure allows them to stay in place longer.

- Characteristics: Greases are rated by their NLGI (National Lubricating Grease Institute) consistency number, ranging from 000 (fluid) to 6 (block). Most linear rail greases are NLGI 0, 1, or 2. They also contain various additives, with PTFE (polytetrafluoroethylene) being popular for its low-friction properties, and Moly (molybdenum disulfide) for high-pressure applications.

- Pros:

- Long-lasting film: Greases adhere well and resist migration, requiring less frequent reapplication.

- Excellent for heavy loads/slow speeds: The thicker film provides better cushioning and load distribution.

- Seals out contaminants: The thick consistency can act as an effective barrier against dust and moisture, protecting the internal components.

- Good adhesion: Stays where applied, reducing mess in enclosed systems.

- Cons:

- Can attract dust/debris: Especially in open environments, the sticky nature of grease can trap airborne particles, turning the lubricant into an abrasive paste if not regularly cleaned.

- Higher resistance to motion: The thicker consistency can introduce slightly more drag, which might be a concern for very delicate, high-speed movements, though usually negligible for 3D printers.

- Messier application: Can be more challenging to apply precisely without specialized tools.

- Specific Types for 3D Printers:

- Lithium-based grease: A common multi-purpose choice, offering good general performance.

- PTFE-based grease: Highly recommended for linear rails due to PTFE's inherent low-friction properties, which further reduces stick-slip.

- Synthetic greases: Often perform well across a wider temperature range and offer enhanced chemical resistance.

Specialized lubricants: Dry lubricants

Dry lubricants like graphite or PTFE sprays are sometimes considered for extremely dusty environments where wet lubricants would attract too much debris. However, they typically offer far less protection against wear and corrosion than oils or greases and are generally not recommended as the primary **linear rail lubrication** for high-precision **3D printer rails** unless specifically designed for the application and component type.

Objective comparison: Features, costs, and application considerations

When selecting between oils and greases for your 3D printer's linear rails, it's not about finding a universally "better" option, but rather understanding the trade-offs and choosing what best suits your specific printer, environment, and maintenance habits. Here's a comparative analysis:

Performance metrics: Oil vs. grease

- Load Bearing Capacity: Greases generally excel here. Their thicker film and ability to remain in place provide superior cushioning and load distribution, making them suitable for heavier print heads or more robust machines. Oils, with their thinner film, are less effective under very high loads or shock conditions.

- Speed Capability: Oils typically allow for higher operating speeds with less resistance. The viscosity of grease, while beneficial for load, can create more drag at very high velocities. For most 3D printer speeds, this difference is often negligible, but for extremely fast machines, oil might offer a slight edge in reducing motor strain.

- Contaminant Resistance: Grease, by its very nature, can act as a barrier, effectively sealing out dust, moisture, and other airborne contaminants from the bearing elements. However, this also means it can trap contaminants on its surface. Oils offer less sealing capability but are also less likely to accumulate large amounts of surface debris.

- Temperature Range: Both oils and greases come in formulations designed for various temperature ranges. Synthetic versions of both tend to offer the broadest operational temperatures. For typical 3D printing environments, most quality lubricants will suffice, but for enclosed, high-temperature chambers, specialized high-temperature greases or oils might be necessary.

- Friction Reduction: Both types of lubricants are highly effective at reducing friction. The mechanism differs slightly: oils provide a hydrodynamic film, while greases provide a thicker boundary layer. For optimal **smooth motion**, both are excellent when properly applied.

Cost structures: Initial vs. long-term

Analyzing the "cost" extends beyond the purchase price of the lubricant itself to encompass application tools, maintenance frequency, and the long-term health of your machine.

- Initial Purchase Price: A tube of high-quality linear rail grease might have a higher upfront cost than a bottle of light machine oil. However, both are relatively inexpensive investments compared to the cost of replacing worn linear rails. Specialized synthetic greases or oils can be more expensive than general-purpose variants.

- Application Tools: Applying grease effectively often benefits from a specialized grease gun with a needle tip or a precise syringe, which represents an additional initial investment. Oils can often be applied with simpler droppers or needle-tip bottles, which are usually less expensive.

- Frequency of Application & Labor Cost: This is where the long-term cost implications become clearer. Greases, due to their staying power, require less frequent reapplication. This translates directly into less time spent on maintenance (a form of labor cost) over the life of the printer. Oils, needing more frequent top-ups, demand more regular attention. If time is a significant constraint, the reduced frequency of grease application might offer a better long-term value proposition.

- Long-term Component Protection: The most significant "cost" factor is the prevention of premature wear. Investing in the correct lubricant and consistent **rail maintenance** is far more cost-effective than replacing entire **3D printer rails** or carriages due to neglect. The choice between oil and grease, based on your printer's specific loads and environment, will influence this long-term protection.

- Impact on Consumables/Waste: Less frequent application means less lubricant consumed over time, potentially leading to less waste and a slightly lower ongoing material cost, though this is usually marginal.

Environmental factors & application environment

- Dusty Environments: In workshops prone to dust and airborne particles, the choice becomes critical. While grease offers a good seal, its stickiness can attract and trap dust on the exterior, potentially forming an abrasive paste if not regularly cleaned. Oils are less prone to attracting large dust particles on their surface but offer less internal sealing. For very dusty environments, an enclosed printer with grease might be a better option, or more frequent cleaning might be needed if using grease in an open setup.

- Enclosed vs. Open Printers: Enclosed printers benefit greatly from grease, as the sealed environment reduces external dust accumulation, allowing the grease to perform its sealing function optimally without becoming overly contaminated. In open printers, the trade-off between grease's sealing ability and its dust-attracting nature needs careful consideration. Oil's tendency to migrate is also less problematic in an open environment where it can be easily wiped away.

Ultimately, the "best" choice for **linear rail lubrication** is highly contextual. A user with an enclosed printer running high-load prints might find a good quality PTFE-based grease ideal, valuing its longevity and sealing properties. Conversely, someone with an open-frame printer performing light, high-speed movements might prefer a specialized linear rail oil for its cleaner application and lower resistance, provided they commit to more frequent reapplication. The key is to weigh these characteristics against your specific operational needs and maintenance capacity.

The art and science of lubrication: A comprehensive process guide

Applying lubricant isn't just about squirting some oil or grease onto the rails. A proper procedure ensures maximum effectiveness and longevity. Safety first: always wear appropriate gloves and eye protection, and ensure good ventilation when using cleaning agents.

Step 1: Preparation and thorough cleaning

This is arguably the most critical step. Applying new lubricant over old, contaminated grease or oil is counterproductive and can introduce abrasive particles into your bearings.

- Why Clean? To remove old, degraded lubricant, accumulated dust, filament debris, and any other contaminants that could act as abrasives.

- Disassembly (If Necessary): For a truly deep clean, especially if the rails are heavily contaminated or showing signs of stiffness, removing the carriages from the rails is ideal. This allows access to all raceways. Be cautious not to lose the tiny ball bearings if disassembling the carriage itself – often, it's better to clean the carriage while it's still assembled on the rail or a dummy rail.

- Cleaning Agents:

- Isopropyl Alcohol (IPA): Excellent for dissolving old oil and light grease, evaporates quickly, and leaves no residue.

- Mineral Spirits (White Spirit): More effective for heavier grease and grime, but requires thorough wiping to remove all residue.

- Dedicated Degreasers: Some manufacturers offer specific degreasers for linear motion components. Always check compatibility.

- Avoid: Harsh solvents like acetone, which can damage plastic components or seals.

- Cleaning Tools: Lint-free cloths, cotton swabs (for tight spaces), small brushes (e.g., old toothbrushes), and compressed air (use cautiously to avoid driving debris further into bearings).

- The Process: Apply your chosen cleaning agent to a lint-free cloth or cotton swab. Thoroughly wipe down the visible parts of the rail and the exterior of the bearing block. Move the carriage back and forth to expose previously hidden sections of the rail. Repeat until no grime is visible. If you've removed the carriage, clean the rail completely, then clean the carriage's exterior and accessible raceways.

- Drying: Ensure all cleaning agents have fully evaporated before applying new lubricant.

Step 2: Application techniques

The method of application varies significantly between grease and oil.

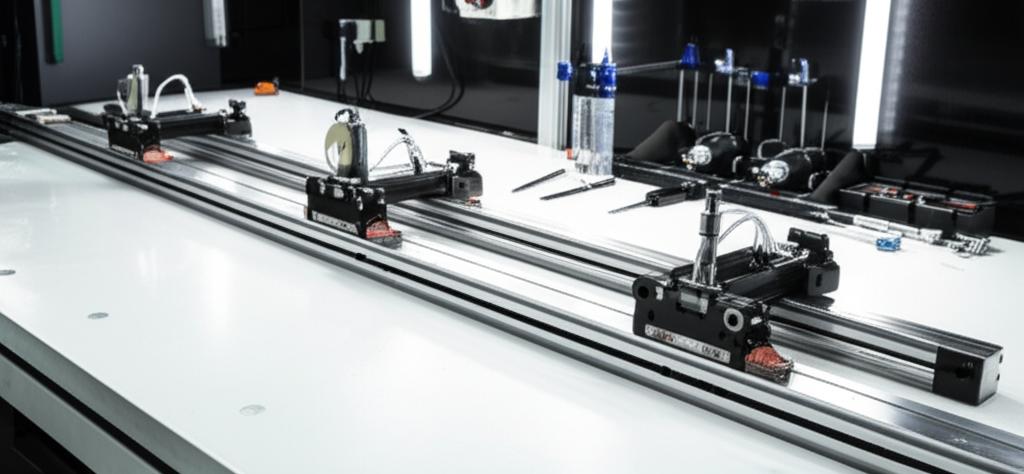

- For Grease:

- Grease Gun with Needle Tip: The most effective method for carriages with dedicated grease ports (often found on larger or industrial-grade linear rails). Attach the needle tip to the port and slowly inject grease until a small amount emerges from the seals or the opposite side.

- Syringe: For smaller MGN-style carriages without grease ports, a small syringe (e.g., a blunt-tip veterinary syringe or a specialized linear rail syringe) is ideal. Apply a small bead of grease directly to the raceways on the rail, or carefully push a tiny amount into the accessible openings of the bearing block.

- Direct Application: For very small amounts, a toothpick or small applicator can be used to dab grease onto the visible raceways.

- Quantity Matters: A common mistake is over-lubrication. A thin, even layer is far more effective than a glob. Excess grease will simply attract more dust.

- For Oil:

- Dropper Bottles/Needle Applicators: These allow for precise control. Apply a few drops directly onto the raceways of the rail.

- Small Brush: A small, clean brush can be used to spread a thin film of oil evenly along the rail.

- Quantity Matters: Again, less is more. A thin, consistent film is what you're aiming for.

Step 3: Distribution and working in

Once the lubricant is applied, it needs to be worked into the bearings.

- Manual Movement: Manually move the carriage back and forth along the entire length of the rail several times. This helps distribute the lubricant evenly and ensures it penetrates the recirculating balls and raceways. You should feel the motion become noticeably smoother.

- Brief Operation: If feasible, run the printer axes that use the lubricated rails through their full range of motion a few times (e.g., using a G-code command like G0 Xmax Ymax Zmax). This can help further distribute the lubricant under operational conditions.

Step 4: Wiping excess

After distribution, use a clean, lint-free cloth to gently wipe away any visible excess lubricant from the exterior of the rails and bearing blocks. This is crucial, especially for grease, as excess lubricant on the surface will attract dust and debris, turning your protective layer into an abrasive one.

Step 5: Reassembly and testing

If you disassembled any parts, reassemble them carefully. Then, manually test the motion of the axes to confirm that they move freely and smoothly. Listen for any unusual sounds.

The direct link: How lubrication elevates print quality

The benefits of proper **linear rail lubrication** extend directly to the quality of your 3D prints, transforming often-frustrating inconsistencies into reliable precision.

- Reduced Vibrations and Ringing: A well-lubricated system moves with less stick-slip friction, meaning the motors don't have to constantly overcome resistance. This results in smoother, more stable motion, which directly reduces vibrations that can cause ghosting, ringing, or salmon skin effects on print surfaces.

- Consistent Layer Adhesion: When the print head moves smoothly and consistently, each layer is deposited uniformly. This leads to better layer adhesion and stronger parts, as the extruder is not fighting against mechanical resistance that could cause momentary underextrusion or inconsistent layer heights.

- Improved Dimensional Accuracy: Friction and wear introduce play and inconsistency into the motion system. By minimizing these, proper lubrication helps maintain the precise positioning required for accurate dimensions, ensuring your printed parts match their digital models more closely.

- Fewer Print Artifacts: Many mysterious print artifacts, such as inconsistent lines, slight shifts, or textural variations, can be traced back to erratic motion caused by dry or contaminated linear rails. Lubrication eliminates these mechanical hindrances, leading to cleaner, more consistent prints.

- Smoother Surface Finishes: The ultimate goal for many is a visually appealing print. A stable and precise motion system, facilitated by optimal **linear rail lubrication**, contributes significantly to achieving exceptionally smooth and consistent surface finishes, free from mechanical imperfections.

Proactive care: Establishing a robust rail maintenance schedule

Consistency is key to effective **rail maintenance**. Establishing a routine for **linear rail lubrication** will ensure your 3D printer remains a high-performance workhorse.

Factors influencing frequency

- Printer Usage: A printer running 24/7 will require more frequent lubrication than one used only occasionally. High-volume production necessitates a more rigorous schedule.

- Environment: Dusty workshops, humid conditions, or environments with airborne filament particles (like ABS fumes) will accelerate lubricant degradation and contamination, demanding more frequent attention.

- Lubricant Type: Greases generally offer longer intervals between applications than oils.

- Load and Speed: Printers with heavier print heads or those operating at very high speeds might benefit from more frequent checks.

General guidelines

- Light Usage (a few hours a week): Check and potentially lubricate every 3-6 months.

- Moderate Usage (daily prints): Check and lubricate every 1-3 months.

- Heavy Usage (24/7 or production environment): Check and lubricate monthly, or even more frequently if visual or auditory cues suggest it.

- New Rails: It's always a good practice to clean and lubricate new **3D printer rails** upon installation, as factory lubrication can be inconsistent or degraded during storage.

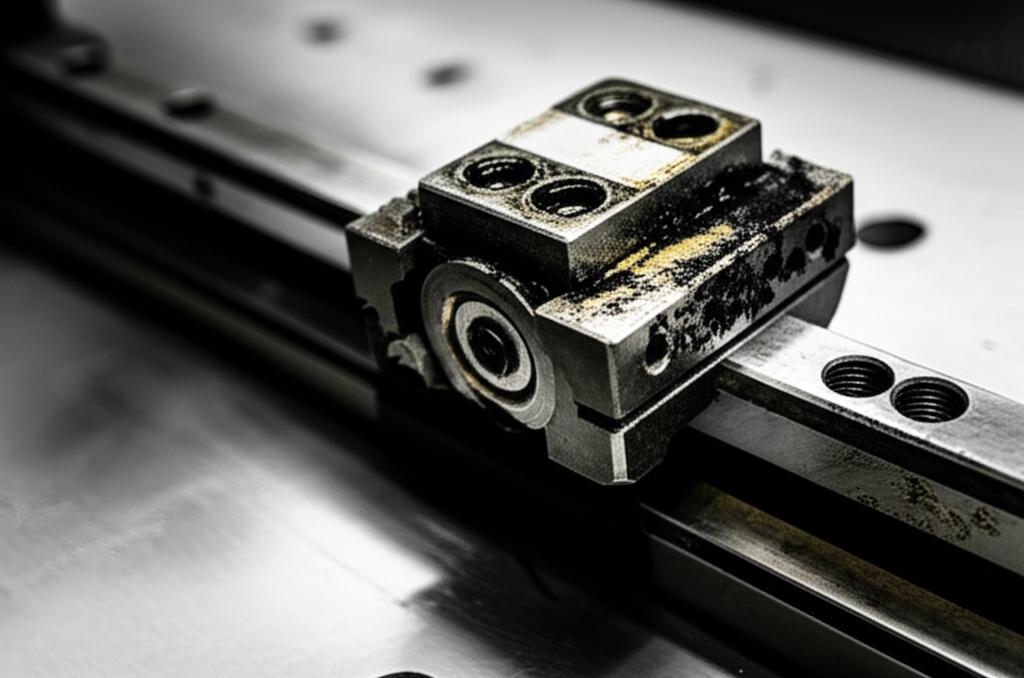

Visual and auditory cues

Your printer often tells you when it needs attention:

- Visual: Look for dry, dusty rails, visible grime around the bearing blocks, or signs of rust.

- Auditory: Listen for increased noise, grinding, squeaking, or a general lack of **smooth motion** during axis movements.

- Tactile: Manually move the print head or bed. Does it feel stiff, notchy, or inconsistent?

Integrating into overall printer maintenance

Think of **linear rail lubrication** as part of a holistic **3D printer maintenance** routine. When you clean your print bed, inspect your nozzle, or check belt tension, take a moment to visually inspect your rails. Proactive care significantly reduces the likelihood of unexpected failures and ensures consistent **print quality**.

Troubleshooting common lubrication missteps

Even with good intentions, mistakes can happen. Knowing common pitfalls can save you headaches and extend the life of your rails.

- Over-lubrication: Applying too much lubricant, especially grease, is a common error. Excess grease will simply attract more dust and debris, turning into an abrasive paste. It can also create unnecessary drag. The fix: Thoroughly clean off the excess and apply a minimal, even layer.

- Under-lubrication: This is the most common form of neglect. Symptoms include increased noise, stiffness, and visible wear. The fix: Clean the rails thoroughly and apply the appropriate lubricant following the guide.

- Using the Wrong Lubricant: Applying a lubricant incompatible with your rail type or environment can be detrimental. For instance, using heavy automotive grease on small MGN rails might introduce too much drag, while using light oil in a very dusty environment might lead to rapid contamination. Always refer to manufacturer recommendations if available, or choose a specialized linear rail lubricant. Avoid lubricants with graphite for ball bearings unless specifically recommended, as graphite particles can be abrasive in this context.

- Neglecting Cleaning Before Lubrication: This is a cardinal sin. Applying fresh lubricant over old, contaminated lubricant or grime effectively seals in the abrasive particles, accelerating wear. Always clean before you lubricate.

- Ignoring Initial Break-in Lubrication: Many new linear rails come with a light factory oil for corrosion protection, not necessarily optimal long-term lubrication. It's often recommended to clean these rails and apply your chosen lubricant before putting them into service.

Conclusion: The smooth path to superior 3D printing

The journey to consistently excellent 3D prints is paved with attention to detail, and few details are as critical as proper **linear rail lubrication**. By understanding the mechanics of your **3D printer rails**, discerning the differences between lubricants, and committing to a diligent **rail maintenance** schedule, you're not just preventing wear—you're actively enhancing your machine's precision, ensuring **smooth motion**, and ultimately elevating your **print quality** to new heights. Embrace this often-overlooked aspect of maintenance, and your 3D printer will reward you with years of reliable, high-fidelity performance.