The first layer of any 3D print is arguably the most critical. It sets the foundation for the entire print, dictating its structural integrity, dimensional accuracy, and overall success. When this foundational layer fails to adhere properly to the build plate, it can lead to a cascade of first layer problems, resulting in wasted filament, lost time, and considerable frustration. While many beginners quickly grasp the basics of leveling a print bed, persistent print adhesion failure, warping prints, and lifting corners often indicate deeper issues that require a more nuanced understanding and systematic approach to troubleshooting.

Understanding the critical role of the first layer

Before diving into specific solutions, it's essential to appreciate why the first layer holds such immense importance. This initial pass of filament serves several key functions:

- Anchoring the print: It must firmly bond with the build surface to prevent movement during the printing process.

- Establishing dimensional accuracy: The first layer's evenness directly impacts the accuracy of subsequent layers and the final part's dimensions.

- Heat transfer: For heated beds, the first layer facilitates efficient heat transfer from the bed to the print, crucial for minimizing thermal stress and warping.

- Surface finish: For prints where the bottom surface is visible, a flawless first layer contributes significantly to the aesthetic quality.

Neglecting these aspects can lead to a range of issues, from minor cosmetic flaws to complete print failures. Addressing first layer problems effectively requires a holistic view of the printing ecosystem, encompassing hardware calibration, material properties, and environmental factors.

Diagnosing common first-layer adhesion issues

Identifying the precise nature of your first-layer problem is the first step toward a solution. While symptoms might appear similar, their underlying causes can vary significantly.

Identifying lifting corners and warping prints

One of the most common and visually frustrating first layer problems is when the edges or corners of your print pull away from the build plate. This phenomenon is known as lifting corners or warping prints.

- Symptoms: The corners of the print curl upwards, detaching from the bed, often pulling the adjacent layers with them. This can lead to the print eventually detaching entirely or cracking.

- Primary Causes: Thermal contraction is the main culprit. As plastic cools, it shrinks. If the print's bond to the bed isn't strong enough to resist this shrinkage, the edges will lift. This is particularly prevalent with materials like ABS, Nylon, and to a lesser extent, PETG, due to their higher glass transition temperatures and greater thermal expansion coefficients compared to PLA.

- Contributing Factors:

- Insufficient bed temperature.

- Excessive cooling from part cooling fans on the first few layers.

- Drafts or significant ambient temperature fluctuations in the printing environment.

- Inadequate build surface prep or an unsuitable build surface for the material.

Recognizing print adhesion failure

Print adhesion failure is a broader term encompassing any situation where the first layer does not stick adequately to the build plate. This can manifest in various ways beyond just warping.

- Symptoms: The filament doesn't stick at all, resulting in a "spaghetti monster" of plastic on the nozzle, or it sticks initially but then detaches completely during the first few layers, causing the print to slide around.

- Primary Causes: This usually points to a fundamental issue with the interface between the nozzle, the filament, and the build surface.

- Contributing Factors:

- Incorrect nozzle height (too high or too low).

- Improper bed temperature for the filament or build surface.

- Poor build surface prep (dirty, oily, or inappropriate surface).

- Under-extrusion on the first layer.

- Worn or damaged nozzle.

Core calibration factors and their solutions

Addressing first layer problems often boils down to meticulously calibrating three core factors: nozzle height, bed temperature, and build surface prep. Each plays a pivotal role, and a deficiency in any one can undermine the others.

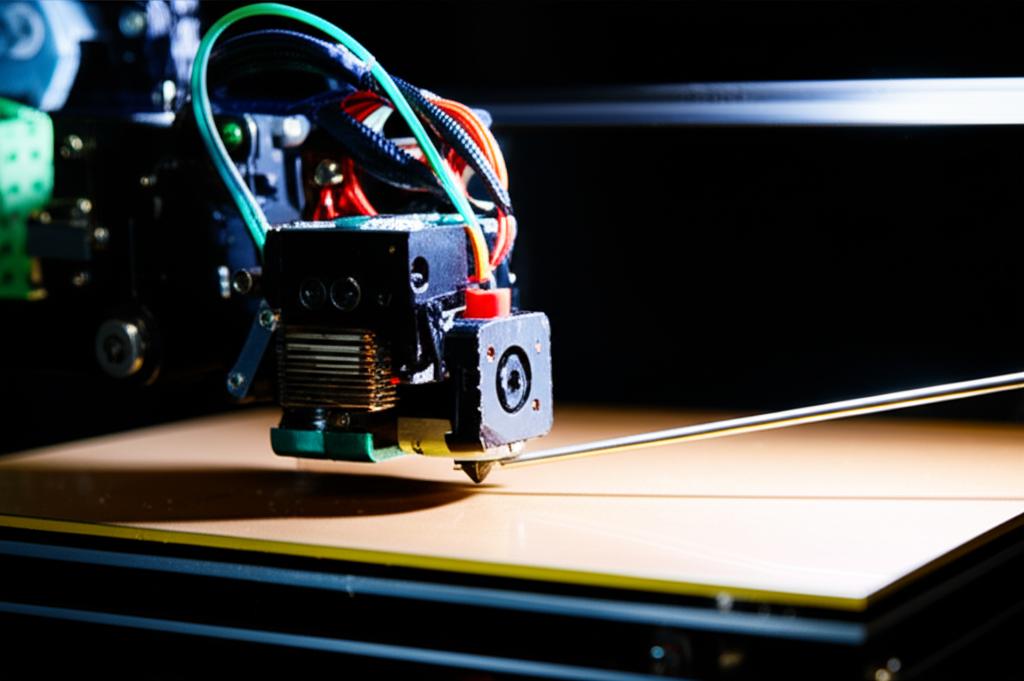

Precision in nozzle height (Z-offset)

The distance between your nozzle and the build plate for the first layer, often referred to as Z-offset, is paramount. This setting determines how much the filament is pressed into the build surface.

- Too High: If the nozzle is too far from the bed, the filament will be laid down as a round strand, with insufficient contact area for adhesion. It might look like a string of beads, easily knocked off.

- Too Low: If the nozzle is too close, it will essentially scrape the build surface, preventing proper filament extrusion. This can lead to thin, translucent lines, skipped extrusion, or even damage to the build surface or nozzle. The filament might also create ridges as it's squished excessively.

Manual vs. assisted leveling (costs, features)

The traditional method of setting nozzle height involves manual bed leveling, typically using a piece of paper. This is a cost-effective approach, requiring only the paper itself and careful adjustment of bed leveling screws. Its features include direct tactile feedback and no additional hardware cost. However, it requires a keen eye, patience, and frequent re-calibration, especially on printers with less rigid frames or beds that shift over time.

Assisted leveling systems often incorporate sensors (e.g., inductive or capacitive probes) that help the user by indicating when the nozzle is at the correct height, or by providing feedback on bed tilt. These systems might add a small cost for the sensor itself (typically $10-$50) but significantly reduce the manual effort and improve consistency compared to purely manual methods. They still require the user to turn the adjustment knobs but offer guided precision.

Automatic Bed Leveling (ABL) systems (costs, features, calibration)

For more advanced users or those seeking maximum convenience, Automatic Bed Leveling (ABL) systems like BLTouch, CRTouch, or inductive/capacitive proximity sensors are popular. These systems automatically probe multiple points on the build plate to create a mesh map of its surface irregularities. The printer's firmware then uses this map to dynamically adjust the Z-axis during the first few layers, compensating for any unevenness.

- Cost: ABL sensors typically range from $30-$80, plus potential costs for mounting brackets or firmware upgrades if your printer doesn't natively support them.

- Features: They offer unparalleled ease of use, reduce the need for frequent manual leveling, and can significantly improve first-layer adhesion consistency across the entire bed, especially on larger or less perfectly flat surfaces.

- Calibration: While ABL automates the *leveling* process, it still requires precise calibration of the Z-offset (the distance between the ABL sensor's trigger point and the actual nozzle tip). This is usually done once through a Z-offset calibration routine in the printer's firmware, often involving a paper test or visual inspection of a test print. Miscalibration of the Z-offset is a common cause of first layer problems even with ABL.

Micro-stepping and live Z-adjust

Even after initial calibration, fine-tuning of the nozzle height can be crucial. Many modern printers offer "live Z-adjust" or "Z-offset adjustment" during the first layer of a print. This allows you to incrementally raise or lower the nozzle in tiny steps (e.g., 0.01mm or 0.025mm) while the first layer is being laid down. This feature is invaluable for dialing in the perfect "squish" for different filaments or build surfaces without stopping the print. It's a feature typically found in firmware and doesn't incur additional hardware costs but requires careful observation.

Optimizing bed temperature for material and surface

The bed temperature plays a critical role in promoting adhesion by keeping the first layer of plastic warm enough to remain slightly pliable, allowing it to conform to the build surface and resist thermal contraction. However, the optimal temperature is highly dependent on the filament material and the type of build surface.

Material-specific considerations (PLA, PETG, ABS, Nylon)

- PLA (Polylactic Acid): Generally the easiest to print, PLA benefits from a bed temperature of 50-65°C. Too high, and it can become overly soft, leading to "elephant's foot" (the first layer spreading out excessively). Too low, and adhesion can suffer, particularly for larger prints.

- PETG (Polyethylene Terephthalate Glycol): Requires higher temperatures, typically 70-85°C. PETG is known for being somewhat sticky, so a higher bed temperature helps it bond, but it can also bond *too well* to some surfaces like bare glass, potentially causing damage upon removal.

- ABS (Acrylonitrile Butadiene Styrene): Highly prone to warping prints due to significant thermal contraction. ABS demands a much higher bed temperature, often 90-110°C, and ideally an enclosed printing environment to maintain warmth.

- Nylon: Similar to ABS, Nylon requires high bed temperatures (60-80°C, sometimes higher depending on type) and often specialized build surfaces or adhesion promoters due to its low surface energy.

Impact of ambient conditions

Drafts and cold ambient temperatures can dramatically impact bed temperature effectiveness. Even if your bed is set to 60°C, a cold draft across the print surface can rapidly cool the filament as it's extruded, leading to premature contraction and lifting corners. This is why enclosures are often recommended for materials like ABS and Nylon.

Heated bed types (aluminum, glass, magnetic flex) and their thermal properties/costs

Different heated bed technologies offer varying thermal performance and features:

- Aluminum Heat Beds: Common in many entry-level and mid-range printers. They heat up relatively quickly and distribute heat fairly well. They often serve as the base for other build surfaces. Cost is typically integrated into the printer's price, or $20-$50 for a replacement.

- Glass Beds: Offer a perfectly flat, smooth surface and excellent heat distribution once heated. They produce a very smooth, glossy bottom finish on prints. However, they can take longer to heat up and may require adhesion promoters (glue stick, hairspray) depending on the material. They are relatively inexpensive ($10-$30) and durable.

- Magnetic Flex Plates (PEI, textured PEI): These systems consist of a magnetic base adhered to the heated bed and a flexible steel sheet coated with a build surface (e.g., PEI, textured PEI). They offer excellent adhesion, especially with PEI, and the ability to easily remove prints by simply flexing the plate. This convenience comes at a higher cost ($30-$60 for a complete system, $15-$30 for replacement sheets) but significantly improves workflow and print removal. Textured PEI offers a unique bottom finish and often better adhesion for some materials than smooth PEI.

When considering different bed types, it's important to weigh the initial cost against the convenience, print quality, and material compatibility they offer. Some cheaper surfaces might require more frequent application of adhesion aids, adding to ongoing operational costs and time.

The art of build surface prep

Even with perfect nozzle height and bed temperature, a poorly prepared or unsuitable build surface prep can lead to catastrophic print adhesion failure. The build surface acts as the physical interface, and its condition is paramount.

Overview of common surfaces (PEI, glass, textured, tape, glue)

- PEI (Polyetherimide) Sheets: Smooth or textured, PEI is a popular choice due to its excellent adhesion properties for a wide range of materials (PLA, PETG, ABS) and relatively low maintenance. Prints often self-release as the bed cools. A smooth PEI sheet provides a glossy bottom finish, while textured PEI offers a matte finish and sometimes even better adhesion. Cost for a PEI sheet on a magnetic flex plate ranges from $15-$30 for a replacement.

- Glass Plates: Known for their flatness and ability to produce extremely smooth, glossy bottom surfaces. They often require adhesion promoters. Cost-effective at $10-$30.

- Painter's Tape (Blue Tape): A classic, low-cost solution for PLA. It provides a slightly textured surface that PLA adheres well to. It's inexpensive ($5-$10 per roll) but requires frequent replacement and can leave residue.

- Glue Stick (PVA-based): A versatile and inexpensive ($2-$5 per stick) adhesion promoter. It works well on glass, PEI, and even painter's tape for various materials, especially PLA and PETG. It provides a sacrificial layer that aids adhesion and print release. Requires reapplication every few prints and cleaning.

- Hairspray (Unscented, extra hold): Similar to glue stick, hairspray creates a sticky layer on glass beds. It's very economical ($5-$10 per can) and can last many prints per application. However, it can create airborne particles and require frequent cleaning of printer components if not applied carefully.

- Specialized Adhesion Liquids/Sprays: Brands like Magigoo or 3DLac offer purpose-built adhesion solutions. These are often more expensive ($15-$30 per bottle/can) but can offer superior adhesion for challenging materials like ABS, Nylon, or Polycarbonate, and are designed for easier cleanup.

Cleaning protocols and tools

Regardless of the build surface, cleanliness is non-negotiable. Fingerprints, dust, and residual plastic or adhesion promoters can severely degrade adhesion. The cleaning protocol depends on the surface:

- PEI: Isopropyl alcohol (IPA) is generally sufficient for daily cleaning. For stubborn grime or when adhesion starts to wane, a light scrub with dish soap and warm water, followed by a thorough rinse, can rejuvenate the surface. Cost of IPA is low ($10-$20 per liter).

- Glass: IPA, window cleaner, or dish soap and water work well. For heavy buildup of glue or hairspray, scraping with a razor blade (carefully!) might be necessary before cleaning with IPA.

- Textured Surfaces: IPA is usually recommended. Avoid abrasive cleaners that could damage the texture.

Tools like microfibre cloths are excellent for wiping down surfaces without leaving lint. For scraping, a plastic scraper is often included with printers, while metal razor blades should be used with extreme caution on glass only.

Adhesion promoters (glue sticks, hairspray, specialized liquids) - cost/effectiveness

Adhesion promoters create a temporary, sacrificial layer on the build surface that enhances the bond with the first layer. Their cost-effectiveness varies:

- Glue Sticks and Hairspray: Very low cost per application, widely available, and effective for many common filaments on glass or PEI. They require regular reapplication and cleaning.

- Specialized Solutions: Higher upfront cost but often more effective for specific, challenging materials and can sometimes last longer between applications. They might also offer easier print release. Their value proposition lies in solving difficult adhesion problems reliably.

When comparing, consider not just the price per unit, but also the frequency of application, ease of cleaning, and the reliability for your specific materials. A cheaper solution that causes frequent print failures might end up costing more in wasted filament and time.

Surface wear and replacement costs

Build surfaces are consumables. Over time, they can become scratched, pitted, or lose their adhesive properties. Recognizing when to replace a surface is key to preventing recurring first layer problems. PEI sheets, for instance, can eventually become less sticky or develop permanent marks. Glass can chip or scratch. Magnetic flex plates can delaminate or warp if overheated.

Replacement costs vary: a new glass plate is relatively inexpensive ($10-$30), while a replacement PEI spring steel sheet might be $15-$30. Factor these long-term costs into your choice of build surface.

Advanced troubleshooting and settings

Beyond the core calibration, several other factors and advanced settings can influence first-layer adhesion, particularly when dealing with persistent first layer problems.

Extrusion consistency and flow rate

The amount of plastic extruded on the first layer is critical. Incorrect extrusion can lead to poor adhesion.

- Under-extrusion: If too little plastic is extruded, the first layer lines will be thin, gappy, and won't properly squish into the bed or fuse with adjacent lines. This directly causes print adhesion failure. This can be due to a partially clogged nozzle, incorrect E-steps calibration, or a flow rate set too low in the slicer.

- Over-extrusion: Too much plastic on the first layer can cause excess material to pile up, creating ridges or waves that the nozzle might crash into on subsequent passes. While it might seem to increase adhesion initially, it can lead to inconsistent layer heights and potential print detachment due to uneven stress.

E-steps Calibration: This calibrates your extruder to ensure it pushes out the correct length of filament. It's a one-time calibration (unless you change your extruder) that directly impacts extrusion accuracy. Online guides provide detailed steps for this process, which typically involves measuring extruded filament and adjusting a value in your printer's firmware.

First Layer Line Width and Speed: In your slicer, you can often specify a wider line width for the first layer (e.g., 120% of nozzle diameter). This puts down more plastic, increasing the contact area and squish, thereby improving adhesion. Similarly, a slower first layer speed (e.g., 15-25 mm/s) allows the plastic more time to bond with the bed and ensures better filament deposition without being pulled by the nozzle's rapid movement.

Environmental factors and enclosures

The environment surrounding your 3D printer plays a significant, often underestimated, role in first-layer success, especially in preventing warping prints.

- Drafts: Even a slight breeze from an open window, air conditioning, or a passing person can cause rapid, uneven cooling of the first layer, leading to severe lifting corners, particularly with temperature-sensitive materials.

- Ambient Temperature: A consistently warm printing environment minimizes the temperature differential between the extruded plastic and the surrounding air, reducing thermal stress.

- Humidity: While less direct for first-layer adhesion, high humidity can cause some filaments (especially Nylon, PVA, PETG) to absorb moisture, leading to poor extrusion quality, bubbles, and inconsistent layers, which can indirectly impact the first layer's integrity.

DIY vs. Commercial Enclosures (cost, features, effectiveness):

- DIY Enclosures: Can be constructed from readily available materials like IKEA Lack tables, foam board, or old cabinets. Costs can range from virtually free to $50-$100. They offer customization and are a budget-friendly way to mitigate drafts and maintain a more stable ambient temperature. Their effectiveness depends on the quality of construction.

- Commercial Enclosures: Range from simple covers ($50-$150) to sophisticated, heated, and filtered enclosures ($200-$500+). They offer professional aesthetics, often better thermal insulation, fire safety features, and integrated ventilation. The higher cost is justified by convenience, safety, and superior environmental control, which is particularly beneficial for high-performance materials like ABS, ASA, and Nylon that are prone to warping prints.

Investing in an enclosure, whether DIY or commercial, can be a game-changer for consistently printing challenging materials and reducing first layer problems.

Mechanical integrity and hardware inspection

Sometimes, first layer problems stem from mechanical issues with the printer itself, rather than just settings. A thorough inspection can save hours of fruitless software adjustments.

- Gantry Alignment: An uneven or sagging X-gantry can cause the nozzle height to vary across the bed, even if the bed itself is perfectly level. This can be due to loose eccentric nuts on rollers, bent rods, or misaligned uprights. Checking for squareness and rigidity is important.

- Belt Tension: Loose or overly tight belts on the X and Y axes can lead to ghosting, layer shifts, or inconsistent movement, indirectly affecting the precision of the first layer. Belts should be taut but not overly strained.

- Worn Components:

- Nozzle: A worn or damaged nozzle can extrude inconsistently or have an uneven opening, leading to poor first layer adhesion. Brass nozzles are consumables and wear out, especially with abrasive filaments. Replacing a brass nozzle is inexpensive ($5-$15 for a pack). Hardened steel or ruby nozzles offer greater longevity for abrasive filaments but come at a higher cost ($15-$100+).

- Build Plate: As discussed, a scratched, warped, or damaged build plate can directly cause adhesion issues.

- Bed Bearings/Wheels: Worn or loose wheels/bearings supporting the print bed can cause it to wobble or tilt during printing, leading to inconsistent nozzle height.

Cost of Replacement Parts vs. Troubleshooting Time: Often, replacing a small, inexpensive component like a nozzle or a set of eccentric nuts can resolve persistent issues far more quickly and effectively than endlessly tweaking settings. Keeping a small stock of common spare parts can be a cost-effective strategy in the long run.

Firmware and slicer settings for first layer success

Your slicer software and printer firmware offer a wealth of settings specifically designed to improve first-layer adhesion and combat first layer problems. Understanding and utilizing these effectively is crucial.

Initial layer speed and fan settings

- Initial Layer Speed: As mentioned, printing the first layer at a significantly slower speed (e.g., 15-25 mm/s) allows the plastic more time to bond with the build surface and ensures precise, even deposition. Most slicers have a dedicated setting for this.

- Initial Layer Fan Speed: For many materials, especially those prone to warping prints like ABS, PETG, and Nylon, it's critical to have the part cooling fan completely off for the first few layers (typically 3-5 layers). This prevents rapid cooling and thermal contraction. For PLA, a low fan speed (e.g., 0-30%) might be acceptable, but often turning it off for the first layer is still beneficial. Gradual increase of fan speed over subsequent layers is a common strategy.

Brim, raft, and skirt strategies

These are print aids generated by the slicer to improve first-layer adhesion and stability:

- Skirt: A line printed around the perimeter of your print, but not touching it. Its primary purpose is to prime the nozzle and ensure consistent extrusion before the actual print begins. It doesn't directly improve adhesion but ensures good flow when the first layer starts.

- Brim: A single or multi-line perimeter printed directly attached to the base of your print. It significantly increases the print's footprint on the build plate, providing a larger adhesion area and counteracting lifting corners and warping prints. Brims are generally easy to remove and leave minimal marks. The number of brim lines can be adjusted in the slicer to increase its effectiveness.

- Raft: A full grid-like base printed underneath your part, with the part then printed on top of the raft. Rafts offer the strongest adhesion support, effectively creating a new, perfectly flat print surface for the part. They are excellent for very small parts or materials highly prone to warping. However, rafts use more filament, take longer to print, and can leave a rougher finish on the bottom of the part, requiring post-processing.

When choosing between these, consider the material, the size and geometry of your print, and the desired bottom surface finish. Brims offer a good balance of adhesion improvement and ease of removal, while rafts are the heavy-duty solution for severe adhesion challenges.

Z-hop and retraction (less direct, but can prevent dragging)

While not directly related to initial adhesion, these settings can prevent issues that might *look* like adhesion problems or exacerbate them:

- Z-hop: When the nozzle moves between non-printing areas, it lifts slightly (hops) to avoid dragging across the already printed part. If your first layer has minor imperfections or "elephant's foot," a dragging nozzle can catch on these, potentially dislodging the print. A Z-hop can prevent this, but it adds to print time and can sometimes increase stringing.

- Retraction: Pulls the filament back into the nozzle slightly during non-printing moves to prevent oozing. While primarily for stringing, consistent retraction ensures that when the nozzle restarts extrusion for a new section of the first layer, it does so cleanly and precisely, preventing blobs that could interfere with adhesion.

Continuous improvement and diagnostic tools

Mastering first-layer adhesion is an ongoing process of learning and refinement. Developing a systematic approach to diagnosis and improvement will serve you well.

Print diagnostics and visual inspection

Become adept at visually inspecting your first layer. Learn to recognize the signs of perfect squish (even, slightly flattened lines that fuse well), under-extrusion (gaps, thin lines), and over-extrusion (ridges, blobs). Take photos of problematic first layers to compare against successful ones. Many online resources offer visual guides to help you identify these nuances.

Test prints and calibration cubes

Don't wait for a large, important print to fail to troubleshoot. Utilize small, quick test prints:

- Single-layer squares or circles: Print a 50x50mm square or circle with just one layer. This allows you to quickly assess nozzle height and adhesion across a small area without wasting much filament or time.

- Calibration cubes: While primarily for dimensional accuracy, printing a calibration cube can also reveal first-layer issues if the base is warped or detaches.

- Adhesion test patterns: Some users design or download specific patterns with varying geometries to test adhesion in different areas and with different shapes (e.g., sharp corners, long straight lines).

These small prints are invaluable for testing changes to bed temperature, nozzle height, or build surface prep without committing to a full print.

Community resources and support

The 3D printing community is vast and incredibly supportive. If you're stuck on persistent first layer problems:

- Online Forums and Subreddits: Websites like Reddit's r/FixMyPrint or specific printer forums are excellent places to post photos of your issues and get advice from experienced users.

- Manufacturer Support: Your printer manufacturer might have dedicated support forums or knowledge bases.

- YouTube Tutorials: Many excellent video guides walk through calibration and troubleshooting steps visually.

When seeking help, always provide as much detail as possible: printer model, filament type, bed temperature, nozzle height settings (if known), build surface prep, and clear photos of the failure.

Conclusion

Conquering first layer problems is a rite of passage for every 3D printing enthusiast. It requires a blend of meticulous calibration, an understanding of material science, and a systematic approach to troubleshooting. By paying close attention to nozzle height, optimizing bed temperature for your specific filament and surface, and ensuring diligent build surface prep, you can dramatically reduce instances of print adhesion failure, warping prints, and lifting corners. Remember that consistent success often comes from a combination of finely tuned settings and a well-maintained printer. Embrace the iterative process of testing and refinement, and you'll soon be laying down perfect first layers with confidence, paving the way for countless successful 3D prints.