The landscape of 3D printing continues to evolve at a rapid pace, pushing the boundaries of what's possible in manufacturing and prototyping. However, a persistent bottleneck in many additive manufacturing workflows has long been the post-processing stage, particularly the often tedious and labor-intensive task of support material removal. Manual support removal can be time-consuming, prone to errors that damage delicate parts, and a significant drain on resources. This challenge has spurred the development of various automated support removal solutions, ranging from sophisticated software algorithms to dedicated hardware systems. Understanding the diverse offerings, their cost structures, and feature sets is crucial for any organization looking to enhance workflow efficiency and achieve consistent part quality.

Understanding automated support removal

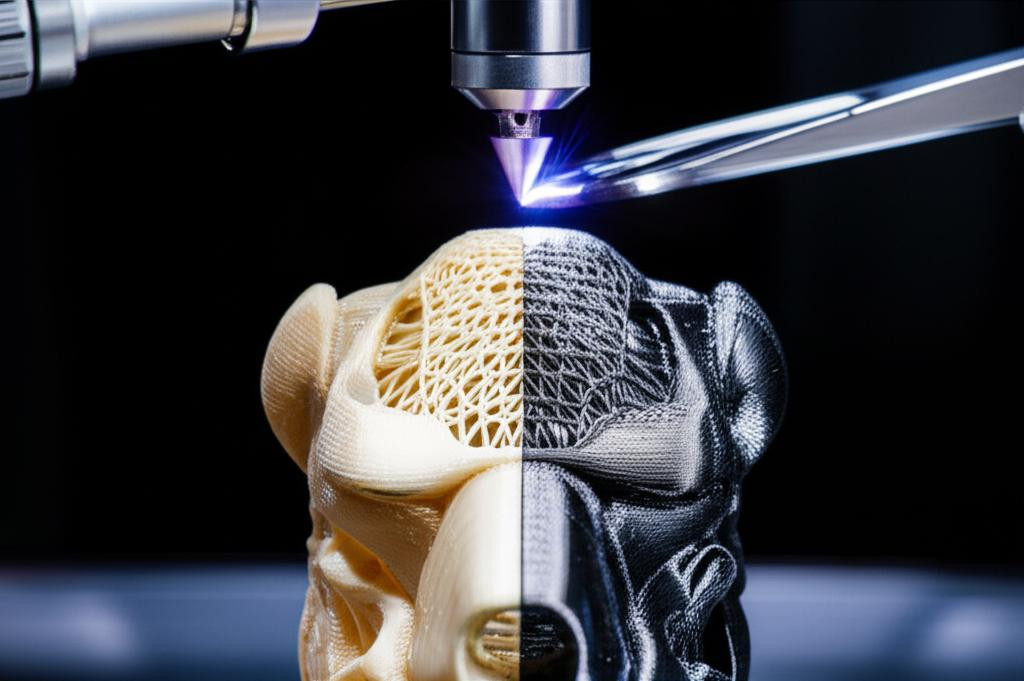

Automated support removal refers to the application of technology to streamline or fully mechanize the process of detaching support structures from 3D printed objects. These supports are essential for bridging overhangs and ensuring structural integrity during the printing process, but their removal is critical for the final part's aesthetic and functional properties. The goal of automation in this context is to minimize manual intervention, reduce post-processing time, improve surface finish, and lower the risk of part damage.

The benefits extend beyond mere convenience. By integrating automated support removal, businesses can often:

- Increase throughput by significantly cutting down post-processing times.

- Achieve greater consistency in part quality, as automated processes are less susceptible to human error.

- Reduce labor costs associated with manual finishing.

- Enable the production of more complex geometries that would be impractical to clean manually.

- Improve workplace safety by minimizing exposure to sharp tools or hazardous materials used in manual removal.

Categories of automated support solutions

Automated support removal solutions broadly fall into two main categories: software-based approaches, which optimize support generation and design for easier removal, and hardware-based systems, which physically remove supports after printing. Each category presents distinct features, cost implications, and operational considerations.

Integrated software within 3D printing slicers

Many modern 3D printing software packages, often referred to as 'slicers,' include built-in features for automated support generation. These tools are typically the first point of contact for users seeking to automate aspects of their workflow. They analyze the 3D model and automatically place supports where necessary, often with options for adjusting density, angle, and type (e.g., tree supports, linear supports).

- Features: Basic automatic support generation, customizable parameters for density and angle, options for different support patterns, and sometimes material-specific presets. Some advanced slicers offer 'paint-on' support functionality or automatic detection of minimal support areas.

- Cost Structure: Often included as part of the 3D printer's ecosystem or as a free, open-source application. While there's no direct cost for the support generation feature itself, the cost is embedded within the overall software or printer purchase. Updates may be free or part of a paid upgrade path for proprietary software.

- Workflow Impact: Seamlessly integrated into the pre-printing stage, requiring no additional software or data transfer. This simplicity is a major advantage for users prioritizing ease of use and a consolidated workflow.

- Considerations: While convenient, these integrated tools may offer limited advanced optimization or specialized support structures compared to dedicated solutions. Users with highly complex geometries or specific surface finish requirements might find their options somewhat constrained.

Dedicated third-party support generation software

Beyond the basic functionalities of slicers, a range of specialized third-party software tools exists, focusing exclusively on advanced support generation and optimization. These applications leverage sophisticated algorithms to create highly efficient, easily removable, and often material-specific support structures. They aim to minimize material usage while maximizing part integrity and post-processing ease.

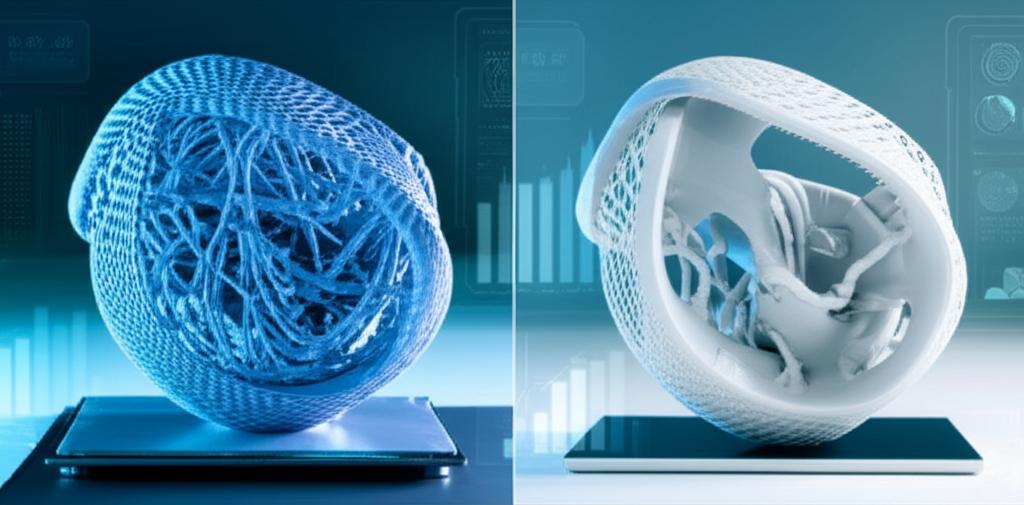

- Features: Advanced algorithmic support generation, intricate custom support structures (e.g., conformal, lattice, or hybrid supports), topological optimization for minimal contact points, simulation tools to predict part deformation, and intelligent slicing for multi-material or soluble supports. Some platforms offer cloud-based processing and AI-driven optimization.

- Cost Structure: Typically involves a subscription model (monthly or annually) or a perpetual license with optional maintenance fees for updates and support. Pricing can vary significantly based on the feature set, user tiers, and enterprise-level functionality. Initial investment can range from hundreds to thousands of dollars, with ongoing costs for subscriptions.

- Workflow Impact: Often requires exporting the model from design software, importing into the support generation software, optimizing, and then exporting back to a slicer. This adds a step to the pre-printing workflow but can yield significant benefits in print success rates and post-processing time.

- Considerations: The learning curve can be steeper due to the advanced features. The investment in these tools is usually justified for professional users, service bureaus, or industries with demanding part complexity, high print volumes, or stringent quality requirements where the benefits of reduced material waste and improved part quality outweigh the software cost.

Automated post-processing hardware solutions

While software optimizes *how* supports are generated, hardware solutions focus on the physical *removal* of supports after the printing process is complete. These systems are designed to automate the often messy and labor-intensive final steps, typically using chemical, mechanical, or thermal processes.

- Features: These machines can range from soluble support removal systems (using water or specialized solvents), abrasive blasting systems (using media like plastic beads), to vibratory tumblers or chemical smoothing stations. Some high-end systems integrate multiple processes or are designed to work with specific 3D printing technologies and materials. They often feature controlled environments, automated cycles, and filtration systems.

- Cost Structure: Represents a significant capital investment, potentially ranging from a few thousand to tens of thousands of dollars or more, depending on the scale, sophistication, and specific technology. Beyond the initial purchase, there are ongoing operational costs for consumables (e.g., solvents, abrasive media, water, filters), utilities (electricity, water), and regular maintenance.

- Workflow Impact: These solutions are integrated into the post-printing stage. Parts are transferred from the printer to the post-processing unit. They can dramatically reduce the manual labor and time spent on support removal, especially for large batches or complex parts. However, they require dedicated space, power, and often specific environmental conditions.

- Considerations: Compatibility with specific print materials is paramount; a soluble support removal system is only effective if the printer uses soluble support materials. Abrasive systems might not be suitable for delicate parts or specific surface finish requirements. Businesses must evaluate the volume of parts, material types, desired surface finish, and available space when considering these substantial investments. Safety protocols for handling chemicals or abrasive media are also crucial.

Key factors influencing selection

Choosing the right automated support removal strategy involves a careful evaluation of several interconnected factors. There is no one-size-fits-all solution, and the optimal choice often involves a combination of software and hardware approaches tailored to specific needs.

- Material Compatibility: The type of filament or resin used dictates the viable support removal methods. Soluble supports require specific hardware and solvents, while brittle materials might be damaged by aggressive mechanical removal.

- Print Volume and Complexity: High-volume production or intricate geometries often justify the investment in advanced software and dedicated hardware for efficiency and consistency. For occasional or simpler prints, integrated slicer functions might suffice.

- Desired Surface Finish: Different removal methods yield varying surface qualities. Chemical smoothing or precise software-generated supports can minimize marks, while some mechanical methods might leave slight imperfections.

- Integration with Existing Workflow: How seamlessly a new solution fits into current design, printing, and finishing processes is vital. Disruptions to workflow can negate the benefits of automation.

- Budget (Initial vs. Operational): Consider not just the upfront purchase price but also recurring costs for software subscriptions, consumables, maintenance, and energy consumption. A seemingly cheaper initial investment might incur higher long-term operational costs.

- Part Functionality and Requirements: Critical parts requiring tight tolerances or specific mechanical properties might benefit from support strategies that minimize internal stresses or part distortion during removal.

Analyzing cost structures and feature sets

When evaluating solutions, it's important to look beyond the sticker price. The true cost of automated support removal encompasses not only direct monetary outlays but also factors like training time, integration efforts, and the potential for material waste or rework if the solution isn't optimal. Software solutions often represent a lower initial barrier to entry, with costs typically tied to licenses or subscriptions, offering flexibility and scalability. Hardware solutions, conversely, demand a significant capital expenditure, with ongoing operational costs for consumables and maintenance that can accumulate over time.

Feature sets also vary widely. Basic slicer-integrated tools provide fundamental automation, suitable for many general-purpose applications. Dedicated software offers granular control and optimization, crucial for complex industrial applications. Hardware post-processing systems offer physical automation, dramatically reducing manual labor for suitable materials and volumes. The key is to match the features offered by a solution with the specific demands of your printing operations, considering the trade-offs between initial investment, recurring costs, and the level of automation and quality achieved.

The journey towards optimized 3D printing post-processing is a strategic one, requiring careful consideration of available technologies and their alignment with specific operational needs. By objectively comparing the cost structures and feature sets of integrated slicer software, dedicated support generation tools, and automated post-processing hardware, organizations can make informed decisions. The ultimate goal is to select a solution, or a combination thereof, that enhances workflow efficiency, improves part quality, and contributes to the overall economic viability of their additive manufacturing endeavors, without compromising on specific project requirements or long-term strategic objectives.