The automotive industry stands at a critical juncture, driven by relentless demands for enhanced fuel efficiency, reduced emissions, and superior vehicle performance. At the heart of meeting these multifaceted challenges lies automotive lightweighting – a strategic imperative focused on reducing the overall mass of a vehicle without compromising its structural integrity or safety. Traditionally, lightweighting has involved meticulous material selection, advanced engineering, and optimized manufacturing processes. However, the advent of additive manufacturing (AM), commonly known as 3D printing, is fundamentally reshaping the landscape, offering unprecedented avenues for creating stronger, lighter, and more complex automotive components.

The imperative of automotive lightweighting

Reducing vehicle weight offers a cascade of benefits. A lighter car requires less energy to accelerate and decelerate, directly translating to improved fuel economy for internal combustion engine vehicles and extended range for electric vehicles. Beyond efficiency, lightweighting contributes significantly to reduced CO2 emissions, a crucial factor in meeting stringent global environmental regulations. From a performance perspective, a lower curb weight enhances handling, braking, and overall agility, providing a more dynamic driving experience. Furthermore, innovative lightweighting solutions can sometimes improve crash safety by allowing for more effective energy absorption in critical zones.

For decades, engineers have pursued lightweighting through various established methods:

- Material substitution: Replacing heavier materials like steel with lighter alternatives such as aluminum alloys, magnesium alloys, or advanced high-strength steels (AHSS).

- Design optimization: Refining component geometries to remove unnecessary material while maintaining structural integrity, often achieved through computer-aided engineering (CAE) tools.

- Component integration: Consolidating multiple parts into a single, lighter assembly, reducing the number of fasteners and manufacturing steps.

Additive manufacturing: A paradigm shift for car parts

Additive manufacturing encompasses a range of technologies that build three-dimensional objects layer by layer from a digital design. Unlike subtractive manufacturing (e.g., machining) or formative manufacturing (e.g., casting, forging), AM offers unparalleled design freedom, making it a powerful tool for automotive lightweighting. Key AM processes relevant to the automotive sector include:

- Selective Laser Sintering (SLS) / Multi Jet Fusion (MJF): Used for polymer parts, enabling complex geometries and functional prototypes.

- Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM): For metal parts, capable of producing high-strength, intricate components from materials like aluminum, titanium, and stainless steel.

- Stereolithography (SLA) / Digital Light Processing (DLP): Primarily for high-resolution polymer prototypes and tooling.

- Fused Deposition Modeling (FDM) / Fused Filament Fabrication (FFF): Common for prototyping and some functional parts with various thermoplastics.

The core advantage of AM in lightweighting lies in its ability to realize designs previously impossible to manufacture. This includes:

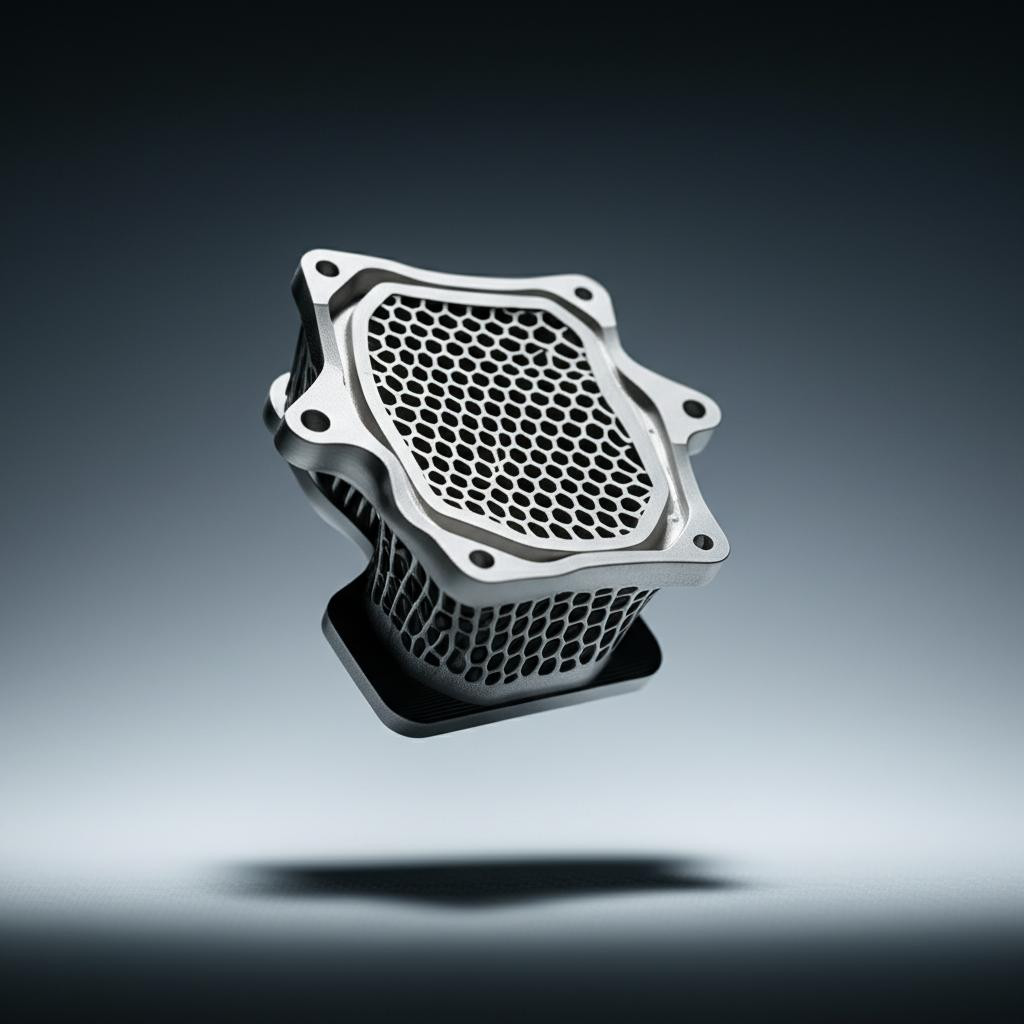

- Complex lattice structures: Internal, porous geometries that offer exceptional strength-to-weight ratio by strategically distributing material where it's most needed.

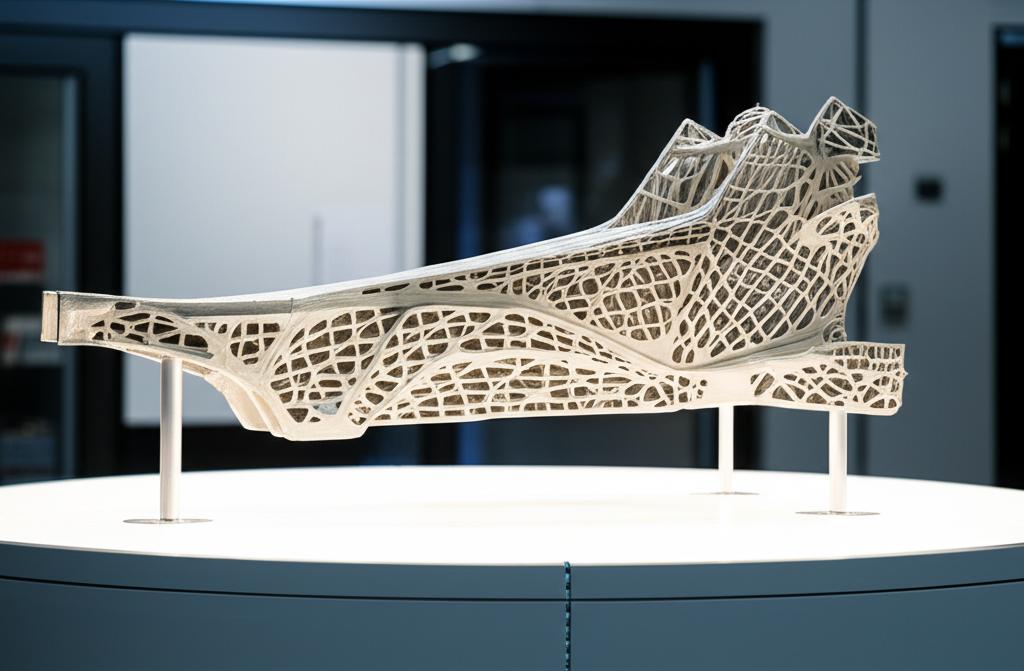

- Topology optimization: Software-driven design processes that generate optimal shapes based on load paths, resulting in organic, often bionic-like forms that are significantly lighter yet equally strong.

- Part consolidation: Combining several conventionally manufactured components into a single, integrated additive manufacturing car part, reducing assembly time and potential failure points.

Comparing lightweighting approaches: Traditional versus additive manufacturing

When considering lightweighting strategies for automotive components, both traditional and additive manufacturing present distinct characteristics regarding material selection, design capabilities, and cost structures. An objective analysis reveals how each approach might best serve specific needs and applications.

Material selection and performance

- Traditional Manufacturing: Relies on a mature ecosystem of well-characterized materials. High-strength steels offer excellent crash performance and cost-effectiveness. Aluminum alloys provide a significant weight reduction over steel, widely used in body structures, engine blocks, and wheels. Composites, particularly carbon fiber reinforced polymers (CFRPs), offer superior strength-to-weight ratios but typically come with higher material and processing costs. These materials often undergo extensive testing and standardization, ensuring predictable performance.

- Additive Manufacturing: Offers a growing palette of advanced materials, including high-performance polymers (e.g., PA12, PEEK), and specialized metal alloys (e.g., titanium, Inconel, specific aluminum alloys like AlSi10Mg). While raw material costs per kilogram for AM powders or resins are generally higher than their traditional counterparts, the ability to use material only where necessary can offset this. AM excels in creating components from exotic alloys that are difficult or impossible to machine or cast, opening doors for extreme performance components in niche applications.

Design freedom and complexity

- Traditional Manufacturing: Design is often constrained by the manufacturing process. Stamping requires consistent wall thicknesses and radii. Casting needs draft angles and core removal. Machining limits internal features. While sophisticated, these methods inherently restrict the geometric complexity achievable, sometimes necessitating compromises in optimal lightweight design.

- Additive Manufacturing: Provides unparalleled design freedom. It allows for the creation of intricate internal channels, complex lattice structures, and organic shapes derived from topology optimization. This enables engineers to achieve truly bionic designs that maximize the strength-to-weight ratio, often leading to significant weight reductions compared to traditionally manufactured parts. This freedom is particularly beneficial for performance components where every gram counts.

Cost structures: A multifaceted perspective

Evaluating the cost-effectiveness of lightweighting solutions requires looking beyond just material prices, encompassing tooling, production volume, lead times, and post-processing.

Initial investment

- Traditional Manufacturing: Often involves substantial upfront investment in tooling, such as molds for casting, dies for stamping, or specialized jigs and fixtures for assembly. These tooling costs are amortized over high production volumes, making traditional methods highly economical for mass production.

- Additive Manufacturing: Requires a significant capital expenditure for AM machines themselves. However, it largely eliminates the need for expensive, dedicated tooling, making it attractive for low-to-medium volume production, rapid prototyping, and custom additive manufacturing car parts.

Material costs and waste

- Traditional Manufacturing: Raw material costs per unit weight are generally lower for common automotive materials. However, processes like machining can generate significant material waste (swarf), and stamping can result in large amounts of scrap material from blanks.

- Additive Manufacturing: Raw materials (powders, resins) tend to be more expensive per kilogram. Yet, AM is inherently an 'additive' process, meaning it builds parts layer by layer, minimizing waste. Unused powder in metal AM, for instance, can often be recycled, contributing to material efficiency.

Production volume and lead time

- Traditional Manufacturing: Excel in high-volume production once tooling is established. Unit costs decrease dramatically with scale. However, lead times for tooling design and manufacturing can be lengthy, delaying product development cycles.

- Additive Manufacturing: Offers rapid prototyping and faster design iteration cycles. It is cost-effective for producing low-to-medium volumes, custom parts, or small batches of highly specialized performance components. While AM build times for individual parts can be longer than traditional methods, the overall time-to-market can be significantly reduced due to the elimination of tooling and design flexibility.

Post-processing and assembly

- Traditional Manufacturing: Often requires multiple post-processing steps (e.g., deburring, heat treatment, surface finishing, welding, assembly of multiple sub-components). These steps add to labor and equipment costs.

- Additive Manufacturing: Also requires post-processing, which can include support structure removal, heat treatment, surface finishing, and sometimes machining for critical tolerances. However, AM's ability to consolidate multiple parts into one can significantly reduce assembly complexity and costs, offering a holistic cost advantage for certain complex assemblies.

Applications and future outlook

While traditional manufacturing remains the backbone of high-volume automotive production, additive manufacturing is increasingly finding its niche in areas where its unique capabilities offer a distinct advantage. This includes:

- Custom and low-volume vehicles: Sports cars, luxury vehicles, and specialized utility vehicles can leverage AM for bespoke components.

- Motorsport: Where extreme strength-to-weight ratios and rapid iteration are paramount, AM is used for critical performance components like suspension uprights, brake calipers, and aerodynamic elements.

- Prototyping and tooling: AM significantly accelerates the development cycle by enabling quick production of functional prototypes and custom manufacturing tools or jigs.

- Spare parts and obsolescence: Producing on-demand spare parts for older or rare vehicles, reducing inventory costs.

The future of automotive lightweighting likely involves a synergistic approach, combining the strengths of both traditional and additive manufacturing. Hybrid processes, where AM is used to create complex internal structures within a conventionally manufactured shell, are also emerging. As AM technologies mature, materials become more cost-effective, and production speeds increase, the integration of additive manufacturing car parts into mainstream automotive production lines is expected to grow. The focus will remain on achieving the optimal balance between performance, cost, and manufacturability, allowing engineers to select the most appropriate technology for each specific component's requirements.