Designing for Additive Manufacturing (DfAM) represents a profound paradigm shift in how engineers approach product development, particularly within the demanding realm of aerospace. Traditionally, manufacturing constraints dictated design, often leading to compromises in performance, weight, and component integration. Additive manufacturing, or 3D printing, has inverted this dynamic, allowing design to lead and manufacturing to follow. This liberation from conventional limitations is especially impactful for DfAM aerospace applications, where every gram saved and every performance gain achieved can have far-reaching implications for fuel efficiency, operational costs, and mission capabilities.

The paradigm shift in aerospace design

The aerospace industry has always been at the forefront of technological innovation, constantly seeking ways to push boundaries in performance, safety, and efficiency. DfAM provides a critical toolkit for achieving these goals by enabling the creation of previously unattainable geometries. Unlike subtractive or formative manufacturing processes, additive manufacturing builds parts layer by layer, allowing for intricate internal structures, organic shapes, and highly optimized forms that would be impossible or prohibitively expensive to produce otherwise. This capability directly addresses the aerospace sector's need for complex aerospace parts that are both lightweight and robust.

Key DfAM methodologies for aerospace

Several advanced design methodologies underpin the success of DfAM in aerospace, each contributing unique benefits to the creation of high-performance components.

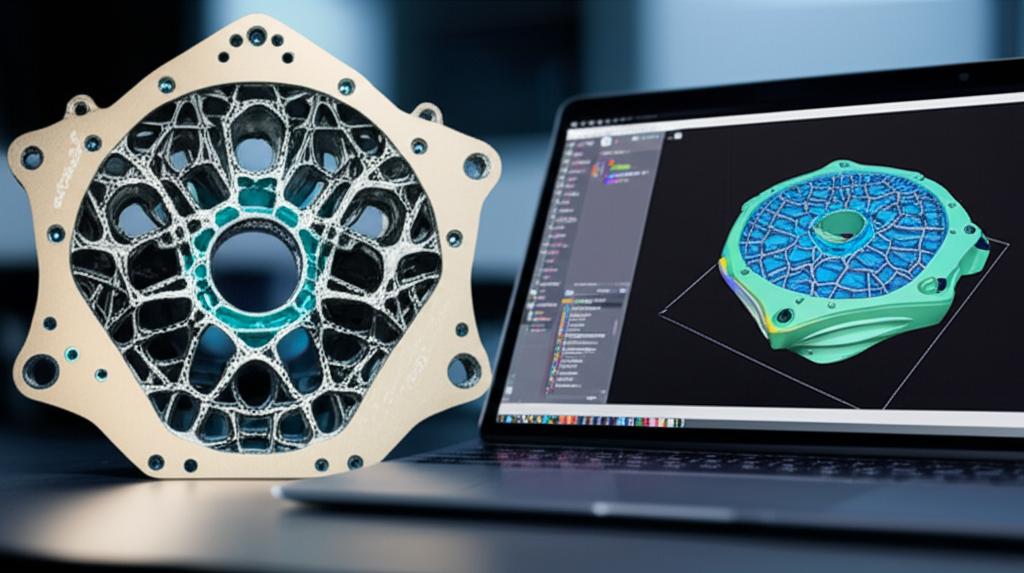

Topology optimization aircraft

Topology optimization is a computational design method that determines the optimal material distribution within a given design space, based on specified loads, boundary conditions, and performance objectives. For topology optimization aircraft components, this often means minimizing mass while maintaining or improving structural integrity. The result is typically an organic, skeletal structure that uses material only where it is absolutely necessary, leading to significant weight reductions – often 20-50% compared to traditionally designed parts. This technique is particularly valuable for brackets, spars, and other structural elements where weight savings directly translate to improved fuel efficiency and payload capacity.

Lattice structures 3D printing

Lattice structures are intricate, repeating cellular patterns that can be integrated into the interior of a component. Lattice structures 3D printing allows engineers to tailor the mechanical properties of a part locally. By varying cell size, strut thickness, and lattice type, designers can achieve exceptional strength-to-weight ratios, superior energy absorption capabilities (for impact resistance), and enhanced thermal management properties. These structures are ideal for applications such as lightweight core materials, heat exchangers, and components requiring specific damping characteristics, offering a level of control over material properties previously unimaginable.

Generative design aviation

Generative design takes optimization a step further by leveraging artificial intelligence and machine learning algorithms. Instead of designers creating a geometry and then optimizing it, generative design software explores thousands, even millions, of design permutations based on a set of high-level performance requirements and constraints. For generative design aviation components, this means rapidly discovering innovative solutions that might not have been conceived by human designers. This iterative process can yield highly optimized, often organic, designs that are perfectly suited for additive manufacturing, accelerating the design cycle and pushing the boundaries of what's possible in aerospace engineering.

Cost considerations and implementation challenges

While the technical advantages of DfAM are clear, the adoption of these methodologies in aerospace involves a careful consideration of cost structures and implementation challenges. The initial investment in DfAM can be substantial, encompassing specialized software licenses, advanced additive manufacturing systems, and comprehensive training for design and manufacturing teams. Material costs for aerospace-grade powders (e.g., titanium, nickel alloys) are often higher per kilogram than traditional bulk materials, though this can be offset by reduced material waste inherent in additive processes.

Furthermore, post-processing requirements for additive parts can add significantly to the overall cost and lead time. These may include heat treatments, surface finishing, and stringent inspection protocols necessary to meet aerospace certification standards. The qualification and certification of additively manufactured parts for flight applications represent a rigorous and often lengthy process, demanding extensive testing and data collection, which adds to the development expenditure.

However, these upfront and developmental costs must be weighed against the potential long-term benefits. The ability to consolidate multiple parts into a single, complex component can reduce assembly time, inventory, and supply chain complexity. Significant weight reductions translate directly into lower fuel consumption over the lifespan of an aircraft, offering substantial operational savings. The enhanced performance and extended component life achieved through DfAM can also reduce maintenance costs and improve overall system reliability. Therefore, while the features offered by DfAM are revolutionary, their economic viability in aerospace is a nuanced calculation, balancing initial outlay with sustained operational advantages and performance gains.

In conclusion, Designing for Additive Manufacturing is not merely an incremental improvement; it is a transformative approach that fundamentally redefines what is achievable in aerospace engineering. By embracing techniques like topology optimization, lattice structures, and generative design, the industry can unlock unprecedented levels of complexity, performance, and efficiency, charting a course for the next generation of aircraft and spacecraft. The journey involves navigating intricate technical and economic landscapes, but the destination promises components that are lighter, stronger, and more capable than ever before.