In the intricate world of 3D printing, where precision is paramount, countless variables can conspire to undermine a perfect print. While common culprits like improper bed leveling or incorrect temperature settings often grab the spotlight, one insidious saboteur frequently operates in the shadows: the worn nozzle. Often overlooked, a degrading nozzle can silently erode your print quality, leading to a myriad of frustrating 3D print defects that go far beyond mere stringing. Understanding its subtle yet significant impact is crucial for anyone aiming to achieve consistent, high-fidelity 3D prints.

The heart of extrusion: understanding the 3D printer nozzle

What a nozzle does: precision and pressure

At its core, the 3D printer nozzle is a marvel of engineering, a tiny yet critical component responsible for transforming molten plastic into the precise shapes that build your 3D models. It's not just a hole; it's a finely machined orifice that dictates the width, height, and consistency of every extruded line. As filament is pushed through the hotend, the nozzle performs several vital functions:

- Shaping the melt: It takes the amorphous molten plastic and forms it into a consistent strand with a precise diameter.

- Controlling flow: The internal geometry and orifice size directly influence the pressure required for extrusion and the rate at which material exits.

- Heat transfer: While the hotend block handles the primary melting, the nozzle's material and design play a role in maintaining the filament's temperature right up to the point of deposition.

Any deviation from its original, pristine state—be it an enlarged orifice, a rough internal channel, or a damaged tip—can have a cascading effect on the entire printing process, leading to a decline in poor print quality that can be difficult to diagnose without understanding the role of nozzle wear.

Nozzle materials and their inherent properties

Nozzles aren't a one-size-fits-all component. They come in various materials, each with distinct properties influencing their performance, longevity, and suitability for different filament types. Understanding these differences is key to making informed choices and mitigating nozzle wear effects:

- Brass nozzles: These are the most common and affordable. Brass offers excellent thermal conductivity, ensuring consistent filament melting. However, it's a relatively soft metal, making it susceptible to wear from abrasive filaments like those containing carbon fiber, glass fiber, or even glow-in-the-dark particles. They are ideal for standard PLA, PETG, and ABS.

- Hardened steel nozzles: A significant step up in durability, hardened steel nozzles are designed to withstand the rigors of abrasive filaments. They are much harder than brass, significantly extending their lifespan when printing composite materials. Their thermal conductivity is lower than brass, which might necessitate slight temperature adjustments. While more expensive than brass, their longevity with abrasive filaments often makes them a cost-effective choice in the long run.

- Stainless steel nozzles: Offering a middle ground in hardness between brass and hardened steel, stainless steel nozzles are often chosen for their food-safe properties (when applicable) and reduced lead content compared to brass. They resist wear better than brass but are still vulnerable to highly abrasive materials. They also have lower thermal conductivity than brass.

- Ruby-tipped nozzles: The crème de la crème of nozzle technology, these feature a tiny industrial ruby embedded in a brass or hardened steel body. The ruby tip is extraordinarily hard, making these nozzles virtually impervious to even the most abrasive filaments. They offer unparalleled longevity and precision, but come with a significantly higher price tag, representing a substantial initial investment for peak performance and durability.

The choice of nozzle material directly influences its resistance to wear. Using the wrong nozzle for an abrasive filament is a surefire way to accelerate its degradation, swiftly leading to a host of print quality issues.

The silent degradation: how a worn nozzle impacts print quality

A worn nozzle doesn't just fail; it degrades, and this gradual deterioration manifests in a diverse range of 3D print defects. These issues can be subtle at first, making diagnosis tricky, but they steadily worsen, turning once-reliable prints into frustrating failures.

Compromised dimensional accuracy and surface finish

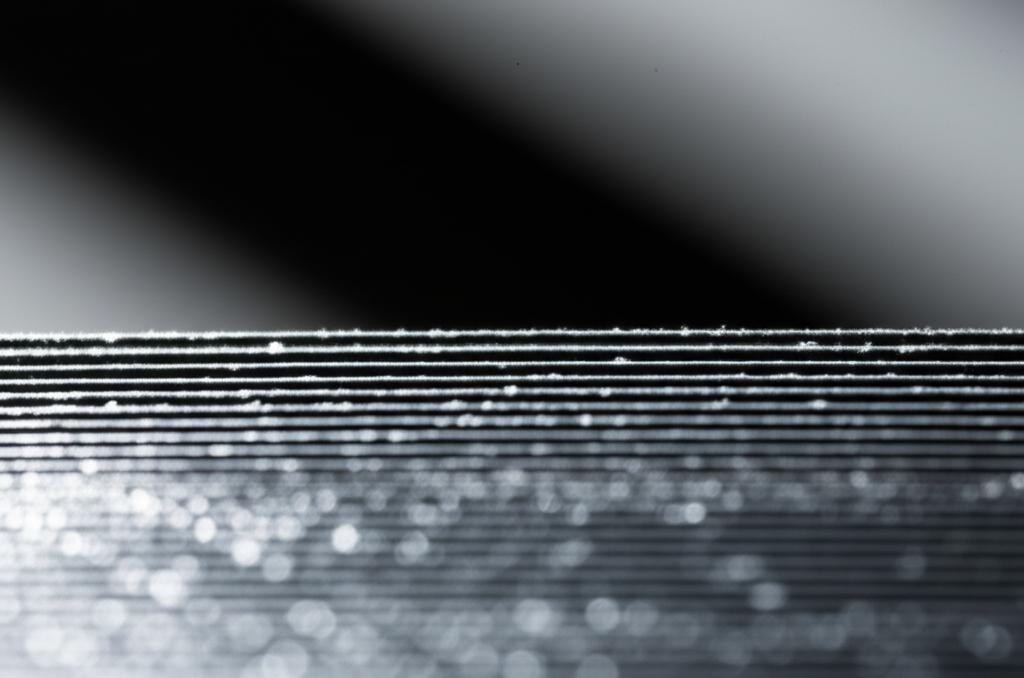

One of the most critical functions of a nozzle is to extrude a consistent, precisely sized line of filament. When the orifice wears, it typically enlarges and often becomes ovalized or irregular. This leads to:

- Inconsistent line widths: Instead of uniform lines, your printer might lay down varying widths, causing uneven infill, weak perimeters, and visible gaps or overlaps.

- Inaccurate part dimensions: An enlarged orifice means more material is extruded than intended, leading to parts that are slightly oversized or have holes that are too small. This is particularly problematic for functional parts requiring tight tolerances.

- Poor wall thickness: The walls of your print may become thinner or thicker than designed, compromising structural integrity and visual appeal.

- Rough surface texture: External damage to the nozzle tip, such as burrs or scratches, can drag across the freshly laid plastic, leaving visible scars, streaks, or a generally rough and inconsistent surface finish.

Under-extrusion, over-extrusion, and inconsistent flow

Nozzle wear isn't limited to the tip; the internal bore can also degrade, becoming rougher or wider in places. This internal friction and altered geometry severely disrupt filament flow:

- Under-extrusion: An enlarged orifice allows filament to flow out more easily, but if the printer's flow rate isn't adjusted, it can lead to less material being deposited than required. This results in weak layers, gaps in perimeters, and incomplete top surfaces.

- Over-extrusion: Paradoxically, internal wear can also cause temporary blockages or pressure fluctuations, leading to sudden bursts of material. More commonly, if the nozzle orifice is simply wider, and the flow rate is not recalibrated, the printer will effectively be over-extruding for the given line width setting.

- Inconsistent flow: The most common issue. The internal resistance changes as the filament passes through an irregularly worn channel, causing the melt pressure to fluctuate. This manifests as uneven lines, sporadic gaps, or random blobs throughout the print.

Ghosting, ringing, and vibrational artifacts

While often attributed to mechanical issues like loose belts or frame resonance, a worn nozzle print quality can exacerbate or even directly contribute to phenomena like ghosting and ringing. An irregular nozzle can cause:

- Erratic extrusion forces: As the nozzle drags across the print or encounters varying resistance due to wear, it can transmit subtle vibrations or forces back into the hotend and gantry.

- Uneven plastic deposition: Inconsistent extrusion due to wear can create slight variations in layer height or width, making existing ghosting more pronounced or introducing new, subtle surface artifacts.

Blobbing, stringing, and oozing: exacerbated issues

These common print issues become significantly harder to control with a worn nozzle:

- Blobbing: External burrs or an irregular nozzle tip can cause molten plastic to stick to the nozzle exterior and then deposit uncontrollably onto the print, creating unsightly blobbing. Inconsistent internal flow can also lead to pressure build-ups and sudden release of excess material.

- Stringing and oozing: An enlarged or irregularly shaped orifice makes it much harder for retraction settings to effectively pull back molten filament. The larger, less defined opening allows more plastic to seep out during non-print moves, leading to increased stringing and oozing, even with optimized retraction settings.

Poor layer adhesion and structural weakness

The foundation of a strong 3D print lies in robust layer adhesion. A worn nozzle undermines this in several ways:

- Inconsistent layer height/width: If the nozzle isn't laying down uniform lines, the contact area between successive layers is compromised.

- Under-extrusion: Gaps and insufficient material deposition directly lead to weaker bonds between layers, making the print prone to delamination and reducing its overall structural integrity. This is a critical aspect of poor print quality.

Visual imperfections: scars, gaps, and rough textures

Beyond the functional issues, a worn nozzle leaves clear visual signatures:

- Visible gaps in top layers: Often caused by under-extrusion or inconsistent line widths.

- Rough side walls: Resulting from the nozzle dragging or uneven extrusion.

- Scarring: Physical damage on the nozzle tip can leave permanent marks on the print surface.

Diagnosing the culprit: identifying a worn nozzle

Identifying a worn nozzle often requires a keen eye and a process of elimination, but certain signs are strong indicators.

The visual tell-tales: external inspection

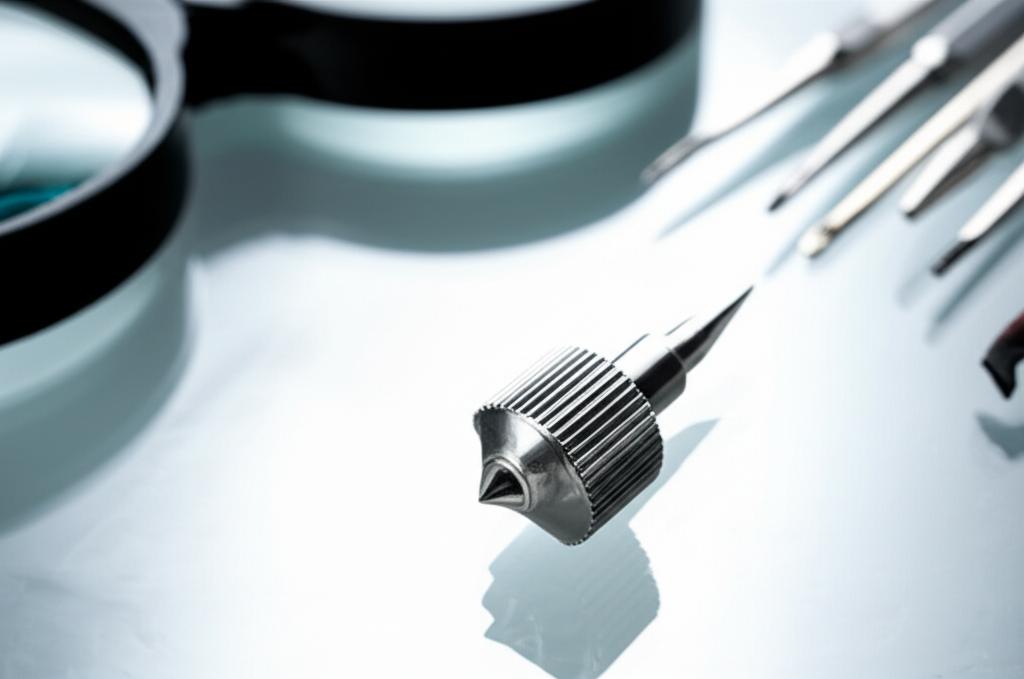

The most direct way to check for wear is a thorough visual inspection. Remove the nozzle (preferably when cold, but carefully if hot) and examine it under good light, ideally with a magnifying glass:

- Deformed tip: Is the tip flattened, rounded, or no longer perfectly conical? Brass nozzles, in particular, can flatten significantly with use.

- Enlarged or irregular orifice: The hole should be perfectly circular and precise. If it appears oval, elongated, or noticeably larger, it's a strong sign of wear. You might even see a burr around the edge.

- Scratches, nicks, or burrs: Look for any physical damage on the outer surface of the nozzle tip. These can drag on the print, causing artifacts.

- Internal bore condition: While harder to see without specialized tools, severe wear can sometimes be inferred if the tip is clearly compromised.

Print quality degradation patterns: what to look for in your prints

When troubleshooting poor print quality, look for patterns that might point to nozzle wear:

- Sudden or gradual decline: Has your print quality consistently worsened over time, or did it take a sharp nosedive after printing a particularly abrasive filament?

- Consistent issues across different models: If multiple, unrelated prints exhibit similar defects (e.g., persistent under-extrusion, blobbing, or surface roughness) that don't respond to typical troubleshooting (temperature, retraction, bed leveling), a worn nozzle is a strong candidate.

- Specific recurring artifacts: Look for recurring gaps, weak layers, or inconsistent line widths that appear systematically.

- Ghosting/ringing that wasn't there before: If you're suddenly seeing these artifacts and haven't changed any mechanical components, consider nozzle wear as a contributing factor.

Performance metrics: flow rate and extrusion consistency

A worn nozzle can also affect your printer's calibration:

- Need for higher flow multiplier: If you find yourself constantly increasing your flow rate or extrusion multiplier to achieve solid top layers or strong perimeters, it could indicate an enlarged nozzle orifice.

- Inconsistent line width: Printing a single-wall test cube and measuring the wall thickness at various points can reveal inconsistencies directly attributable to an irregular nozzle.

Proactive measures: mitigating nozzle wear and maintaining quality

Prevention and timely intervention are key to avoiding the headaches caused by worn nozzle print quality.

Choosing the optimal nozzle for your filament type

This is perhaps the most crucial preventative step. The cost-benefit analysis here is clear: a slightly more expensive hardened steel or ruby nozzle can save you countless hours of troubleshooting and wasted filament if you regularly print with abrasive materials.

- Standard filaments (PLA, PETG, ABS, ASA, TPU): Brass nozzles are perfectly adequate and cost-effective.

- Abrasive filaments (carbon fiber, glass fiber, glow-in-the-dark, wood, metal composites): Opt for hardened steel or ruby-tipped nozzles. While the initial cost is higher, their superior wear resistance ensures consistent print quality and a much longer lifespan, ultimately saving money and frustration.

Best practices for nozzle care and cleaning

Even the toughest nozzles benefit from proper care:

- Regular cleaning: Perform cold pulls to remove internal debris and use a brass brush (never steel, which can scratch softer nozzles) to clean the exterior of the nozzle when hot.

- Avoid harsh scraping: Don't use metal tools to scrape solidified plastic off the nozzle, as this can easily damage the tip.

- Gentle handling: When installing or removing nozzles, avoid over-tightening or using excessive force, which can strip threads or deform the nozzle.

When to replace: a practical guide

There's no fixed schedule for nozzle replacement, as it depends heavily on usage and filament types. However, consider these factors:

- Print quality degradation: If you've tried all other troubleshooting steps and your poor print quality persists, especially with the symptoms described above, it's time for a new nozzle.

- Filament type and print hours: If you've printed hundreds of hours with abrasive filaments on a brass nozzle, replacement is almost certainly due. Even with standard filaments, a brass nozzle will eventually wear down.

- Visual inspection: If the tip is visibly deformed or the orifice is clearly irregular, replace it without hesitation.

- Cost-effectiveness: A new brass nozzle costs only a few dollars. The cost of replacing a worn nozzle is almost always far less than the cost of wasted filament, failed prints, and lost time due to persistent quality issues. As the adage goes, "when in doubt, swap it out."

The true cost of inaction: beyond the print bed

Neglecting a worn nozzle might seem like a minor oversight, but its repercussions extend far beyond just a few failed prints. The cumulative costs can be substantial, both tangible and intangible.

Wasted time and material: the tangible losses

Every failed print due to a worn nozzle represents wasted filament, which translates directly into financial loss. Moreover, the time spent waiting for a print to fail, stopping it, cleaning the print bed, and starting over is invaluable. If you're running a print farm or relying on your printer for production, these losses quickly compound, impacting deadlines and profitability. The constant need to troubleshoot 3D print defects also diverts attention from more productive tasks.

Frustration and lost productivity: the intangible impact

The psychological toll of repeatedly battling poor print quality can be significant. Constant failures lead to frustration, reduce enthusiasm for 3D printing, and can even cause users to abandon projects. For businesses, this translates into lost productivity and potential delays in product development or client deliverables.

Potential damage to other components

While less common, a severely worn nozzle can indirectly stress other hotend components. For instance, an irregular or partially clogged nozzle might require higher extrusion forces, putting strain on the extruder motor or leading to filament grinding. Frequent, severe clogs due to internal wear could also lead to filament backing up into the hotend, potentially damaging the heat break or causing leaks.

The humble 3D printer nozzle is a small component with a monumental impact on print quality. Its wear, often subtle and gradual, can silently undermine the precision and aesthetics of your creations, leading to a frustrating array of 3D print defects, from ghosting and blobbing to poor layer adhesion and compromised dimensional accuracy. By understanding the nozzle wear effects, regularly inspecting your nozzles, choosing the right material for your filaments, and replacing them proactively, you can safeguard your worn nozzle print quality against degradation. Embracing proactive maintenance isn't just about replacing a part; it's about preserving the joy and efficiency of 3D printing, ensuring that every print lives up to its full potential.